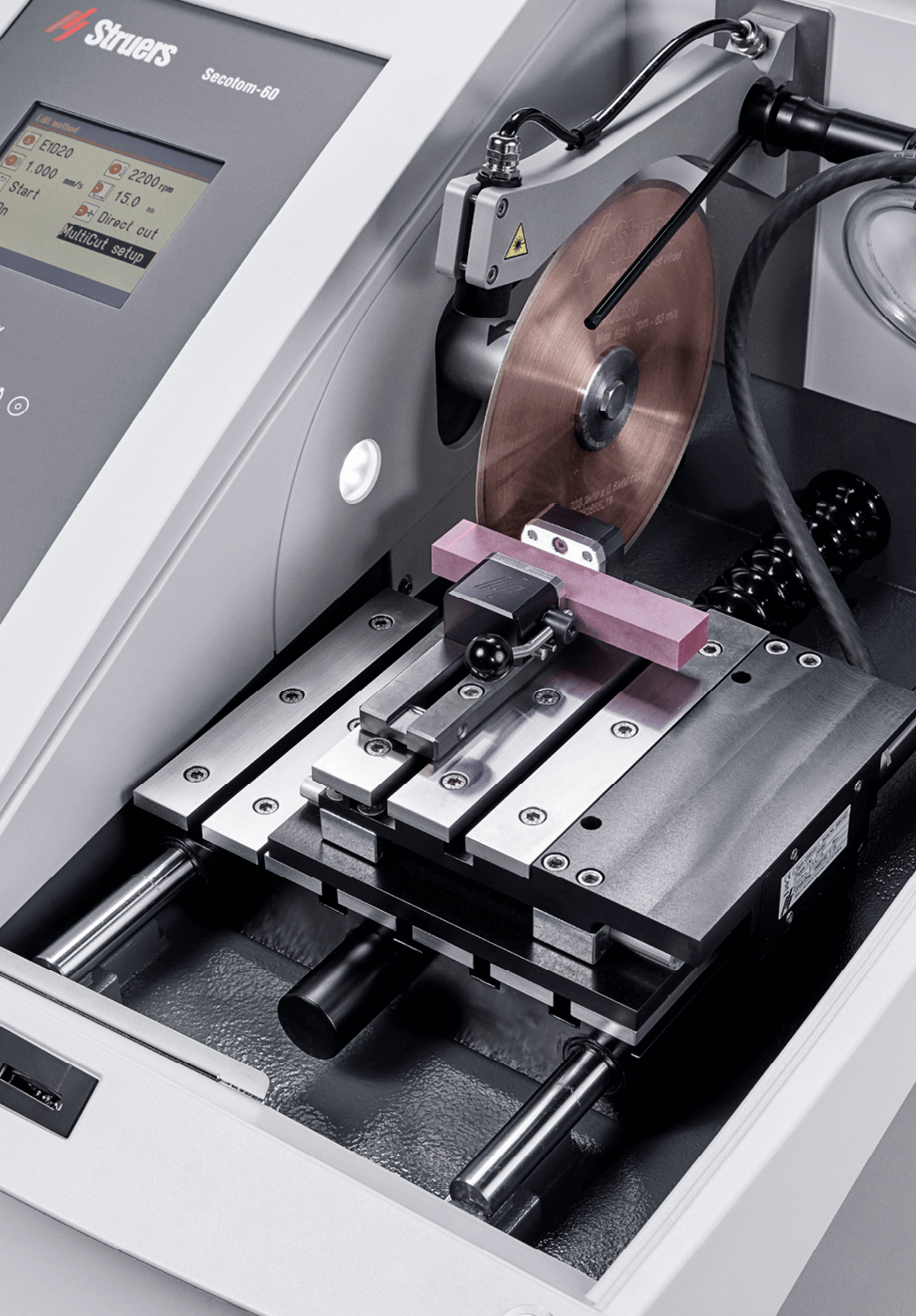

Secotom

- Cutting capacity 50 x 165 mm.

- Automatic precision cutting machine

- Cut-off wheel size 75 – 203 mm/ 3- 8” dia.

- Intuitive user interface for easy operation

- Ultra-flexible T-slot table for precision cutting

- Automatic X-movement for cutting series

- Laser light for precise positioning

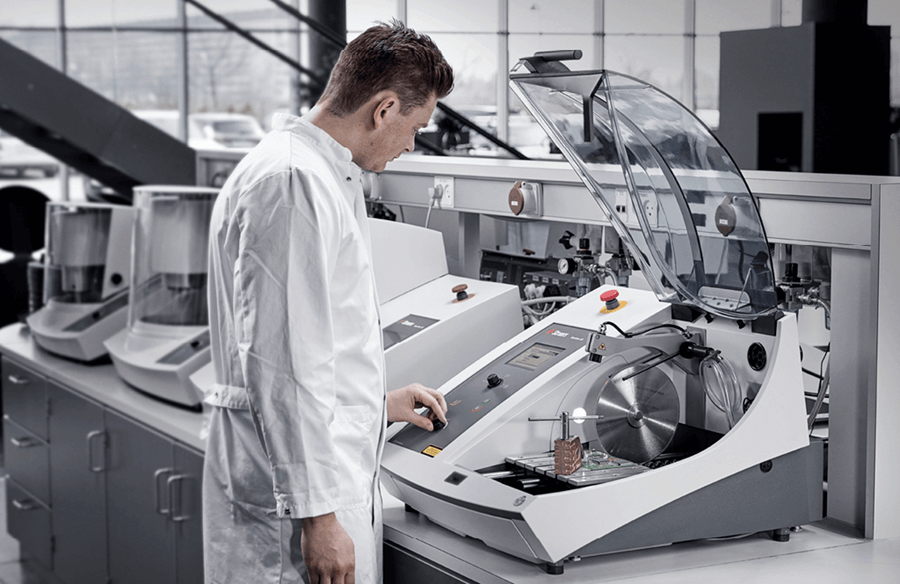

The very first Secotom precision cutting machine was launched in 2001 and became an immediate success. Since then, thousands of Secotoms have left our production to serve laboratories worldwide. An intuitive user interface means that hardly any training is required. The optional automatic X-movement supersedes time-wasting re-positioning, and a movable T-slot table allows for sectioning a range of sizes and shapes. Secotom contains multiple additional features such as a laser light, an ExciCut mode for hard materials, and intelligent feed control.

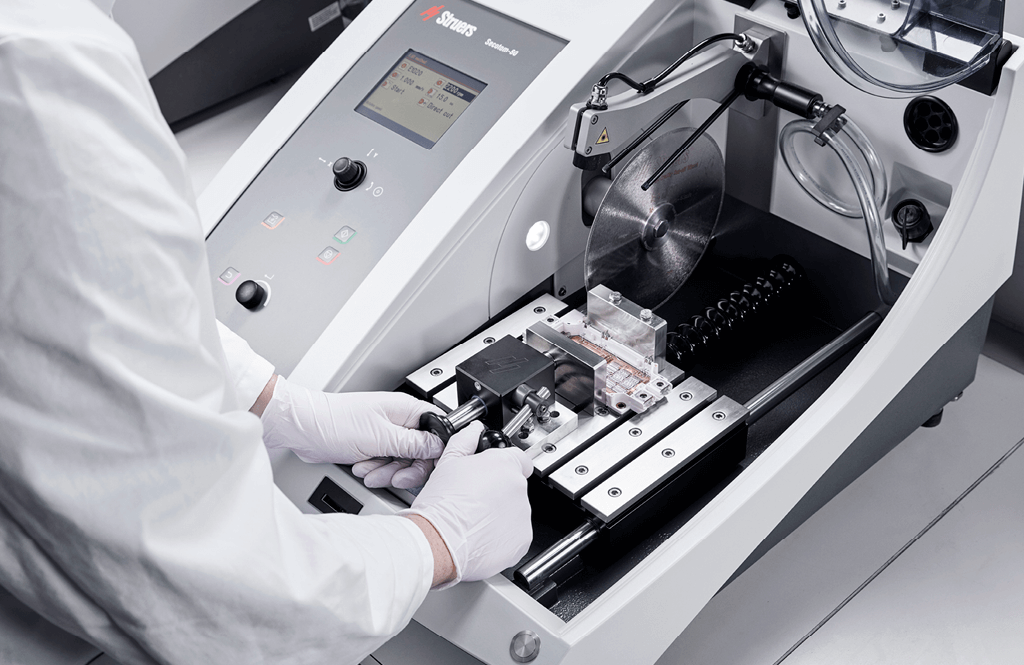

Scarcely any training is required due to the easy settings with an intuitive user interface

A simple user interface and a color display make for ultra-easy operation. There are no complex menus. Set the parameters with a multifunction knob and use the joystick for fast positioning of the workpiece, as well as automatic height adjustment of the cut-off wheel. That’s it.Re-positioning of a workpiece is superseded by the automatic X-movement

Make a series of cuts without wasting time on re-positioning your workpiece, with the optional X-movement. The table has 40 mm movement, and you can choose up to four slides of different thicknesses.Achieve the right position on the first attempt with a little help from the positioning laser light

Positioning can be time-consuming, but the positioning laser light on Secotom makes the job much easier by pointing out the position for your section. Use the laser light in combination with the joystick for easy positioning.Section a wide range of sizes and shapes with ultra-flexible and movable T-slot table

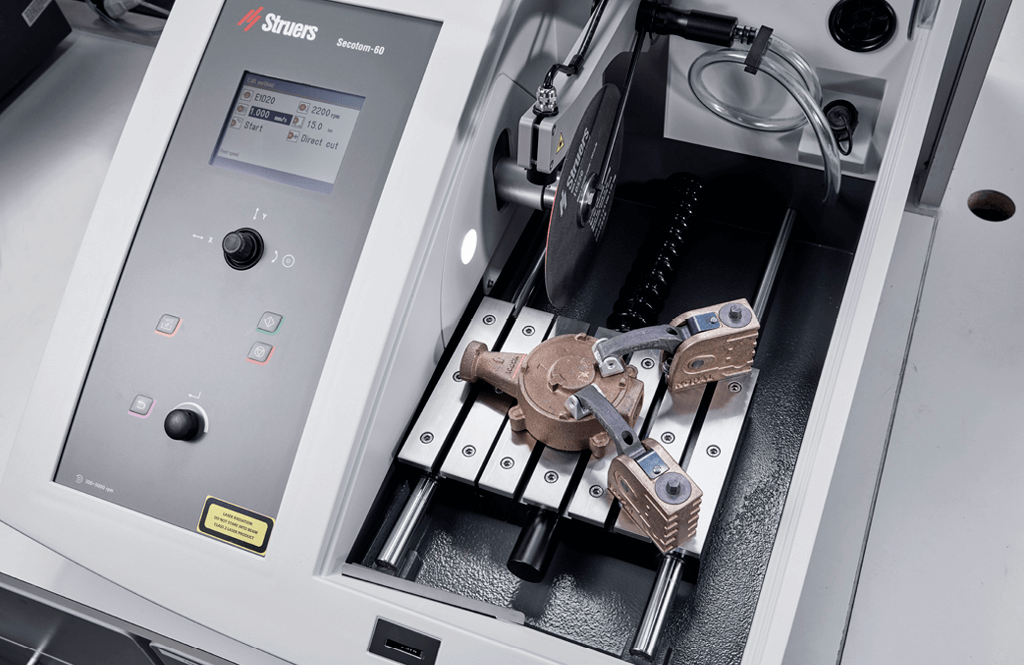

The cutting table in Secotom allows you both ultra-precision and flexibility for a wide range sizes and shapes. You are able to section large and deep workpieces (up to 70 mm / 2.8” diameter or 165 x 50 mm / 6.5”x2). The table has 8 mm t-slots and you can choose between a wide range of clamping tools to find just the right fit for your cut and the highest degree of precision.New case: This combination created the perfect precision cut

Video: See the updated Secotom precision cutting machine in action

See more benefits in the brochure

Key features for the optimal precision cut:

-

Video: A unique look behind the protective shield of the updated Secotom precision cutter

Discover all the advantages of one of our most popular precision cutting machines, the Secotom, in this unique look behind its protective shield. You will experience the automatic X-movement, which supersedes re-positioning of the workpiece, the super easy settings that require hardly any training, the option of sectioning a wide range of sizes, shapes, and material with the ultra-flexible T-slot table - and much more.

Video: A unique look behind the protective shield of the updated Secotom precision cutter

-

Laser light points out the position for your cut

The laser light is a great help when clamping, as it points out the position for your cut. This makes positioning easy and fast.

Laser light points out the position for your cut

-

Intuitive user interface makes for ultra-easy operation

The Secotom requires no programming, and there is no risk of your getting lost in complex menus. It is designed with a large color display for easy operation. The navigation and change of parameters works quickly and easily by a turn/push knob.

Intuitive user interface makes for ultra-easy operation

-

Large, movable table for sectioning large and deep workpieces

The cutting table measures 258 x 184 mm / 12.2" x 7.2" and is ideal for sectioning large and deep workpieces. The flexibility of this large cutting table makes it optimal for clamping.

Large, movable table for sectioning large and deep workpieces

-

Automatic X-movement for serial cutting without re-positioning

An optional X-table allows for serial cutting without re-positioning which make the cutting sequence much faster.

Automatic X-movement for serial cutting without re-positioning

-

Cut-off wheel height adjustment

The cut-off wheel in Secotom can be height adjusted to a range of 40 mm (1.6") which makes it possible to use a variety of clamping tools and stands for dovetail specimen holders. In addition, it enables the use of a large variety of cut-off wheel sizes, and makes it easy to compensate for wheel wear.

Cut-off wheel height adjustment

-

Build-in recirculation cooling tank for a smaller footprint

The build-in recirculation tank grants you a smaller footprint and better accessibility. The tank has a barrier inside to catch the largest cutting debris which reduces blockage of the cooling nozzles.

Build-in recirculation cooling tank for a smaller footprint

-

ExciCut mode for hard materials minimizes the risk of thermal damage

ExciCut is used when sectioning extremely hard materials that cannot be sectioned directly, minimizing the risk of thermal damage of the workpiece. ExciCut works by moving the cut-off wheel up and down as the cutting table moves forward. This ensures that a small contact area between the cut-off wheel and the workpiece and provides better access for the coolant.

ExciCut mode for hard materials minimizes the risk of thermal damage

-

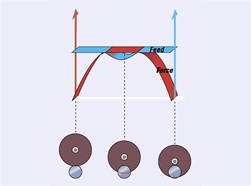

OptiFeed intelligent feed control to avoid motor overload

Sectioning irregular sized workpieces can be difficult, as the risk of damage to the workpiece or the cut-off wheel is high. As the contact area between the workpiece and wheel gets larger, the force increases to maintain the preset feed speed, and this may overload the cut-off machine. But thanks to OptiFeed, the feed speed is automatically reduced in this situation, and when the contact area gets smaller again, the feed speed is automatically increased to the preset maximum.

OptiFeed intelligent feed control to avoid motor overload

-

Direct connection to external exhaust system

Sectioning certain materials may produce both harmful and unpleasant fumes. For a healthier environment, Secotom is prepared for direct connection to an external exhaust system, in line with our general recommendation to install an exhaust from the cutting chamber.

Direct connection to external exhaust system

-

Optional Manual Dresser

The manual dresser makes it easy to dress diamond and CBN cut-off wheels.

The cutting ability gradually reduces when sectioning, and the cut-off wheel rim will appear shiny because of the workpiece’s material deposits on the wheel surface and wear on the abrasive. The cutting ability can be restored by dressing, and the manual dresser makes it easy. You can even dress while sectioning to ensure the best result.Optional Manual Dresser

Facts

Model types

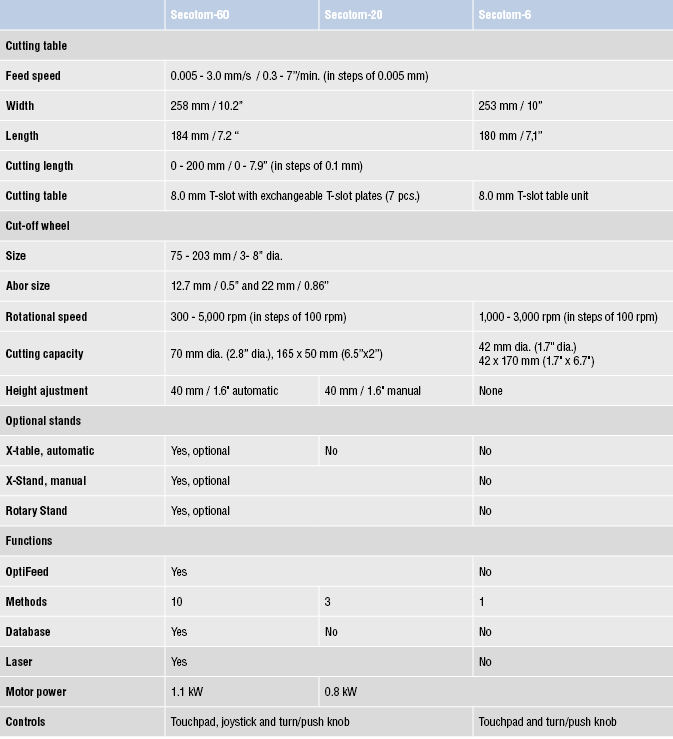

Secotom is available in three versions.

Secotom-60

Secotom-60 is ideal for cuts on a variety of workpieces that require changes to the clamping setup and cut-off wheel position. With features such as an 8.0 mm T-slot with exchangeable T-slot plates, a touchpad, a joystick and a turn/push knob, intelligent feed control, a laser light, ten stored methods, a database, and an optional automatic X-table.Secotom-20

Secotom-20 is ideal for single cuts on a variety of workpieces that require small changes to the clamping setup and the cut-off wheel position. With features such as an 8.0 mm T-slot with exchangeable T-slot plates, a touchpad, a joystick and a turn/push knob, intelligent feed control, three stored methods, and a laser.Secotom-6

Secotom-6 is ideal for single cuts on standard workpieces with minimal changes between jobs. With features such as an 8.0 mm T-slot table unit, a touchpad and a turn/push knob, and one stored method.

Struers’ equipment is in conformity with the provisions of the applicable International Directives and their appurtenant Standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes in our products without notice.

Get Your Technical Data Sheet for Secotom

A short and clear description that gives you an immediate overview to help you make the best choice of equipment.

• Capacity and performance specifications

• Dimensions and weight

• Electrical data

• Noice levels

• Safety

Get Your Brochure for Secotom

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory photos

• Key feature descriptions

• Technical Data Sheet

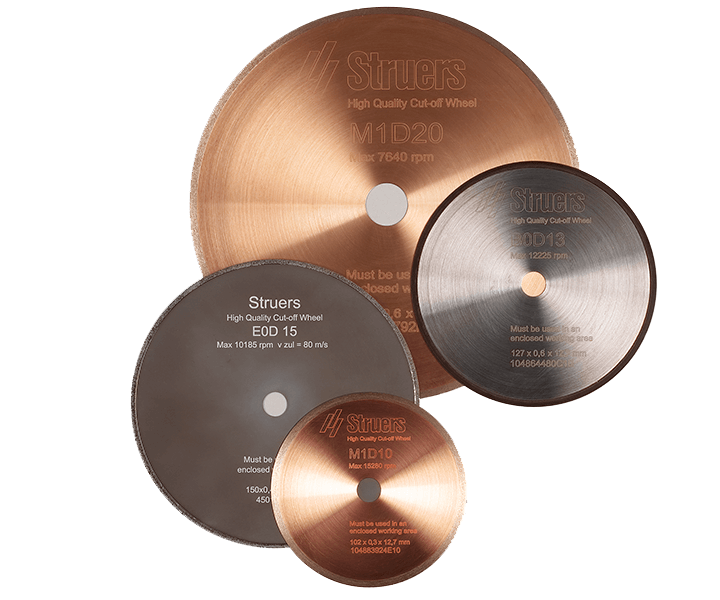

Cutting consumables

-

Abrasive cut-off wheels

Extremely hard ferrous metal (500 < HV < 1400).

Go to webshop Contact sales -

Abrasive cut-off wheels

Very hard ferrous metal (400 < HV < 800).

Go to webshop Contact sales -

Abrasive cut-off wheels

Hard Ferrous metal (275 < HV < 750).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium hard ferrous metal (200 < HV < 550).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium soft ferrous metal (100 < HV < 500).

Go to webshop Contact sales -

Abrasive cut-off wheels

Soft ferrous metal (75 < HV < 375).

Go to webshop Contact sales -

Diamond cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

CBN cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

Additives for cutting

For recirculation, cooling and cleaning.

Go to webshop Contact sales -

+

-

−

Challenge

At Siemens Industrial Turbomachinery, they wanted to increase their precision sectioning even more when preparing turbines components for materialographic analysis. They wanted to be faster and more efficient and have a more efficient clamping solution for oddly shaped and tiny workpieces.

Solution

Siemens Industrial Turbomachinery chose the Secotom-60 precision cutting machine for their lab. Not only because of the cutting machines’ great certainty but also because it is important for Siemens to be supported by a great materialographic knowledge bank such as Struers.

Result

With the Secotom precision cutting machine, the lab got a fast, silent and easy to operate cutting experience with no limit clamping options due to the ultra-flexible T-slot table.

Mikael Berggren, Laboratory Technician, Siemens Industrial Turbomachinery

Read the case storyRelated products

Minitom

- Workpieces up to 30 x 40 mm

- High-precision tabletop machine

- Low speed protects against heat deformation

A small, low-speed, automatic precision cutting machine for sectioning delicate materialographic workpieces that can’t tolerate th...

Accutom-10/-100

- High precision

- Shorter cutting time

- Higher productivity

The redesigned Accutom cut-off machines from Struers are optimized for precision and ease of use to give the user a head start in ...

Discotom-100/-10

- OptiFeed – intelligent feed control

- AxioWash* (Automatic cleaning)

- ExciCut for very hard materials

Discotom-10 and Discotom-100 are versatile tabletop cut-off machines, designed to give you a cost-efficient opportunity to expand ...

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer

We have always experienced extremely repeatable and consistent, high-quality results. The consistency and reliability of our Struers cutting machines was instrumental in our decision to install a similar Struers system in our plant in Indonesia.Grinding Media, Moly-Cop (Australia) Glenn Sullivan Technical Developments Manager

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor