Lubricant

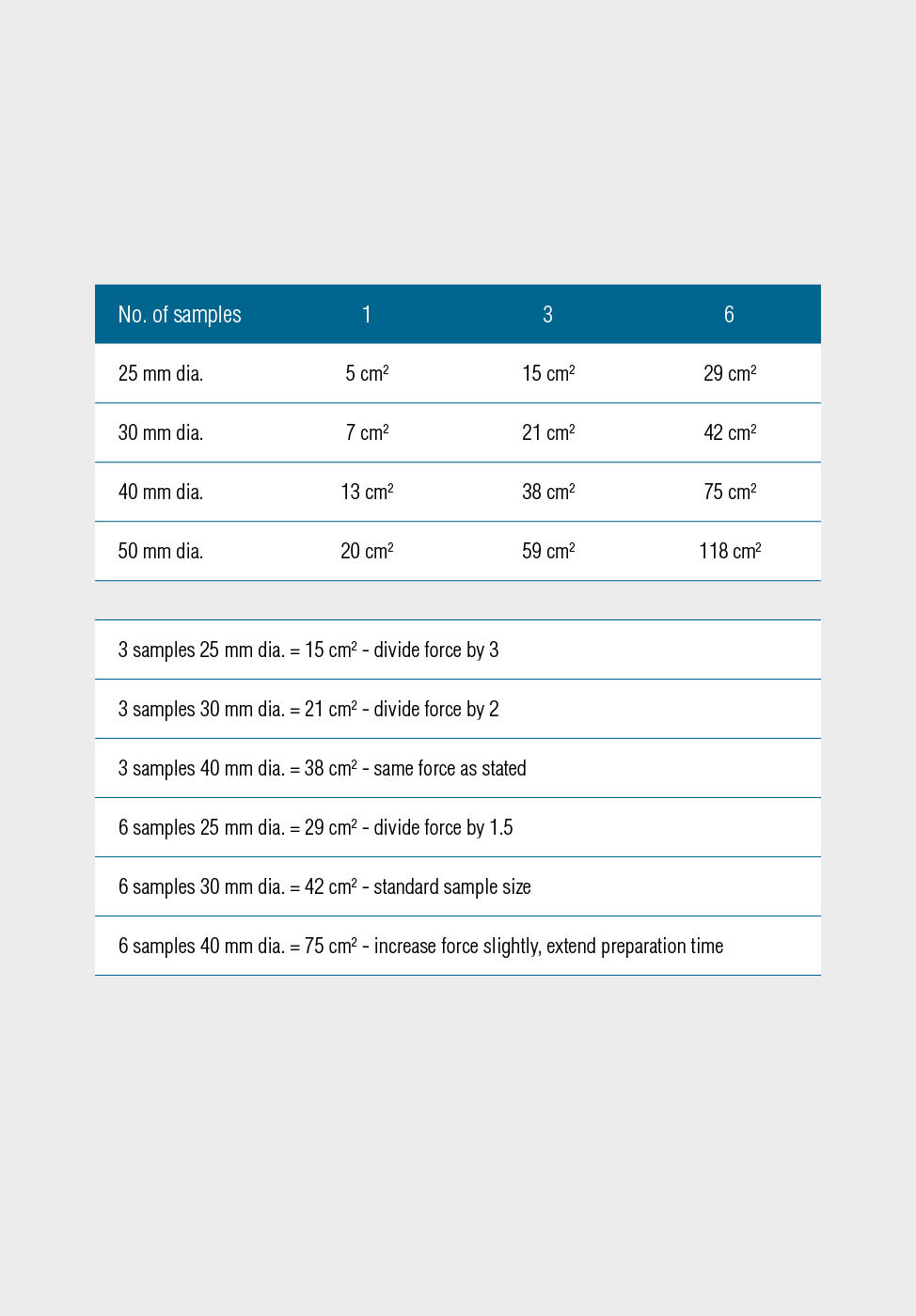

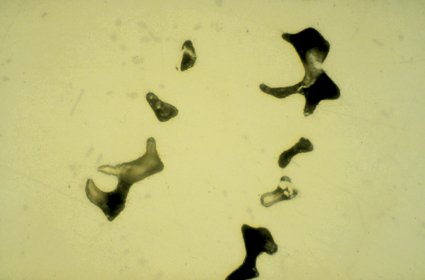

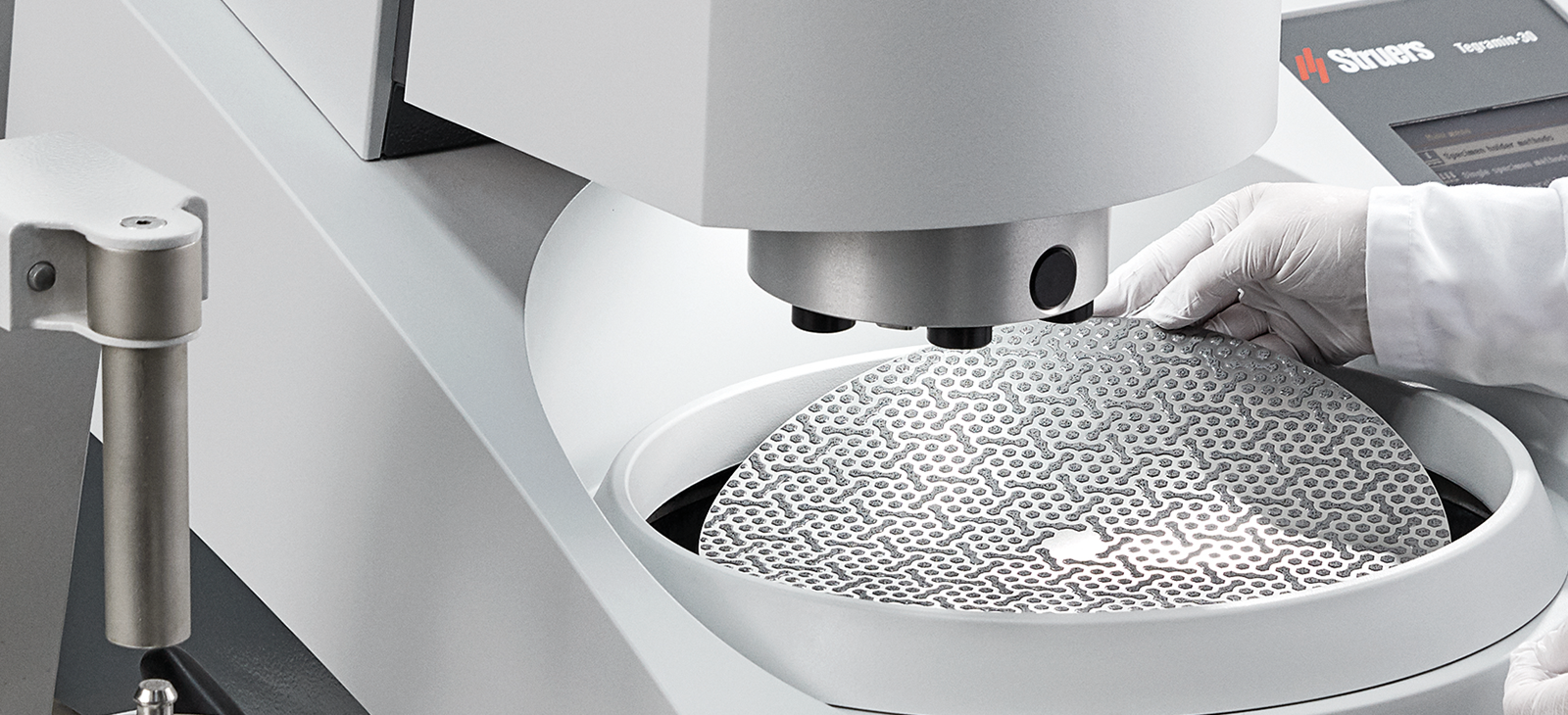

Depending on the type of material and the preparation stage, different lubricants combine levels of lubricating and cooling levels and liquid characteristics.

This may include thin lubricants with high cooling and low lubrication effect, special lubricants for polishing of soft and ductile materials, alcohol-based or water-based, etc.

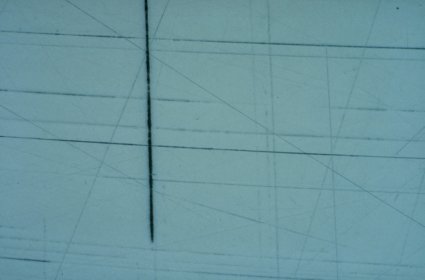

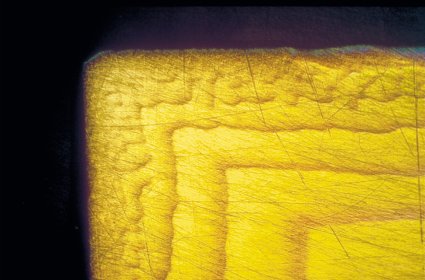

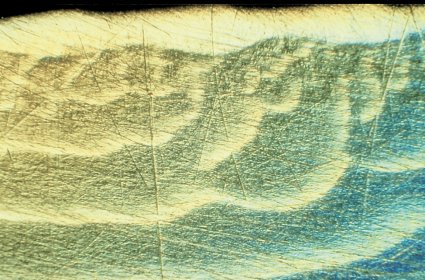

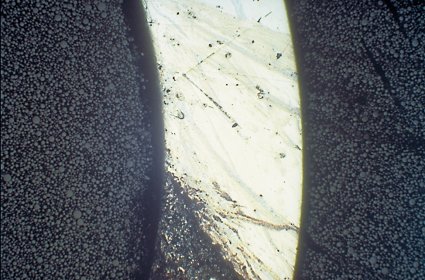

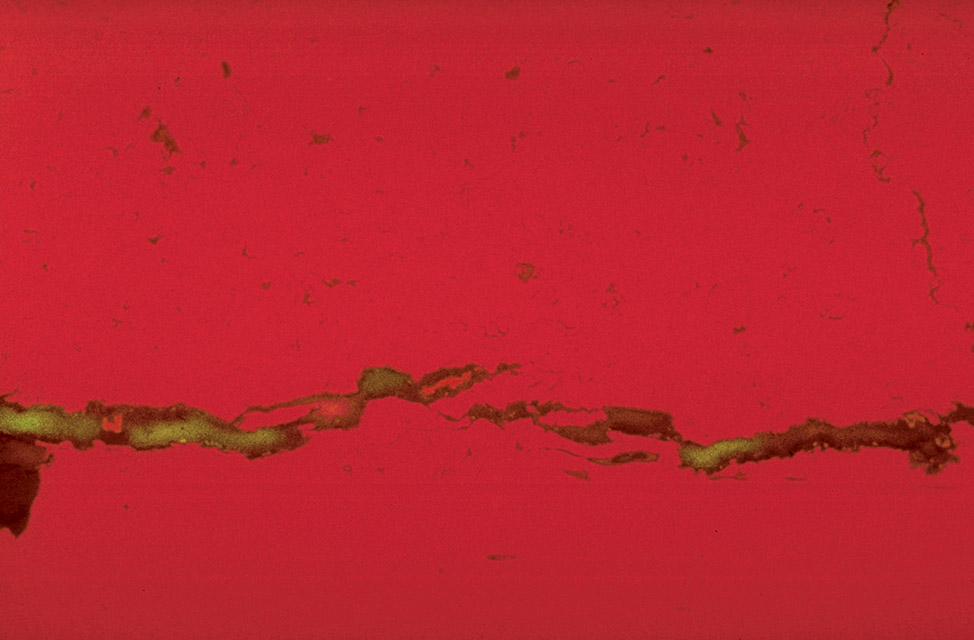

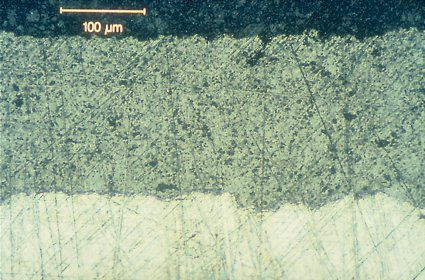

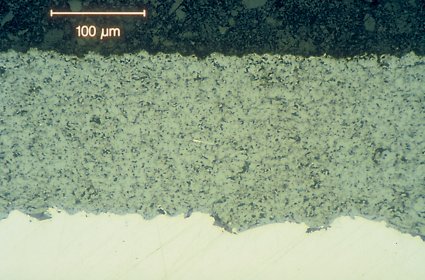

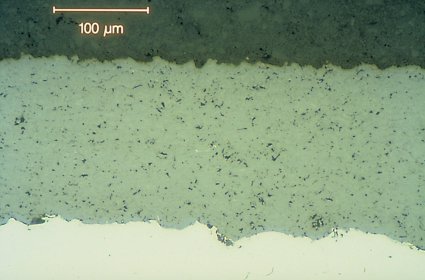

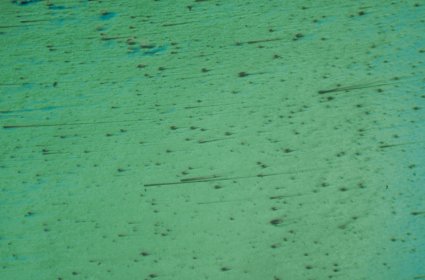

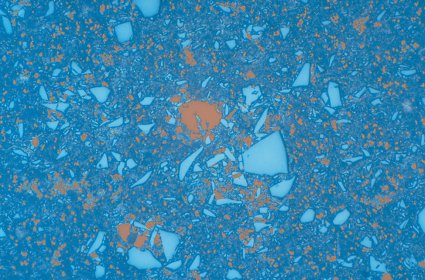

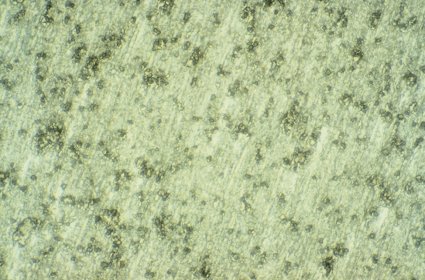

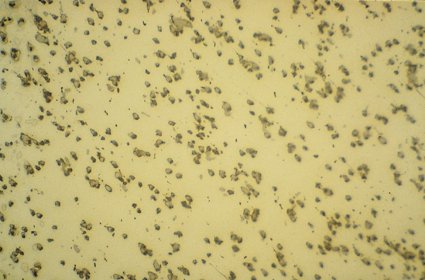

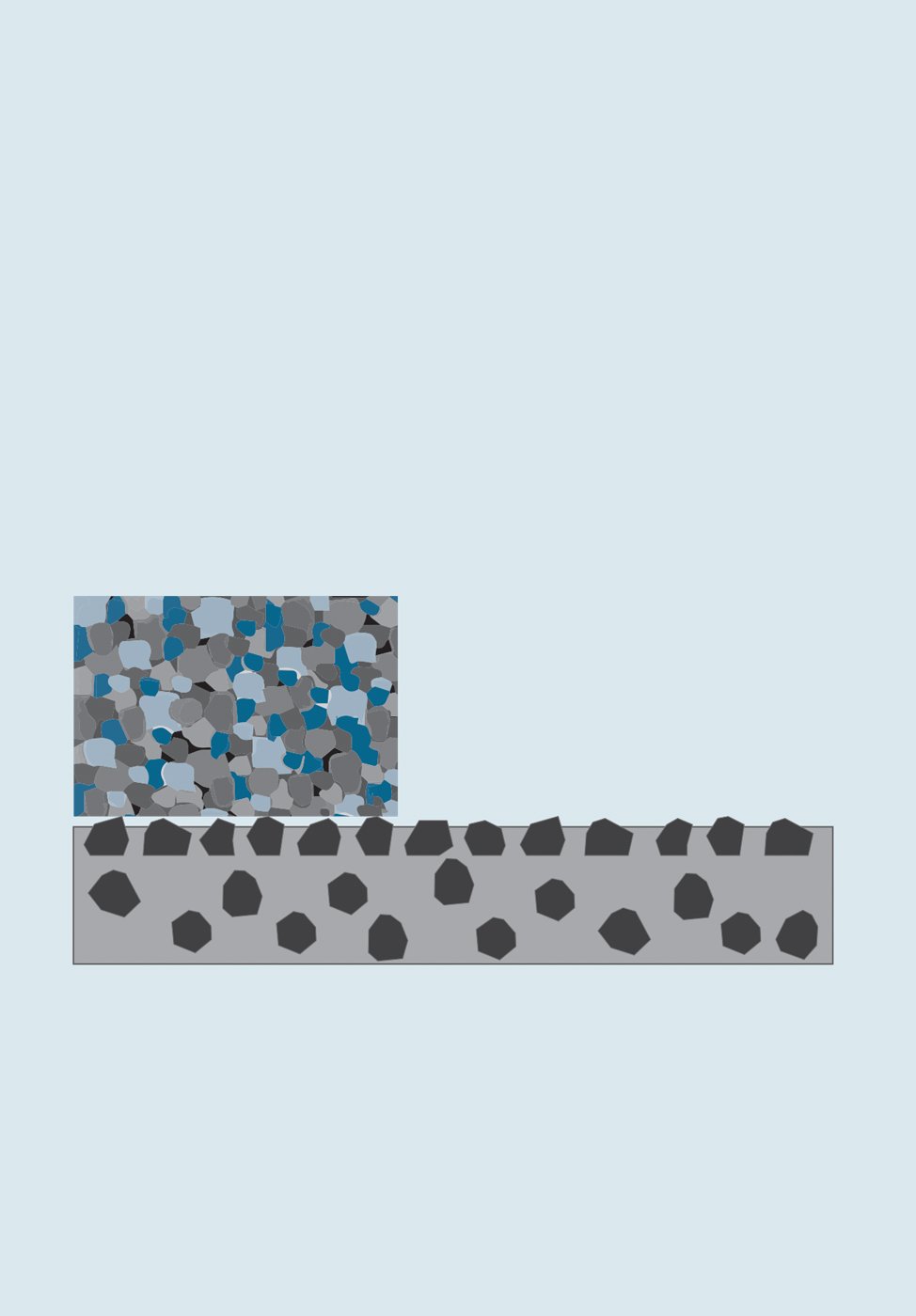

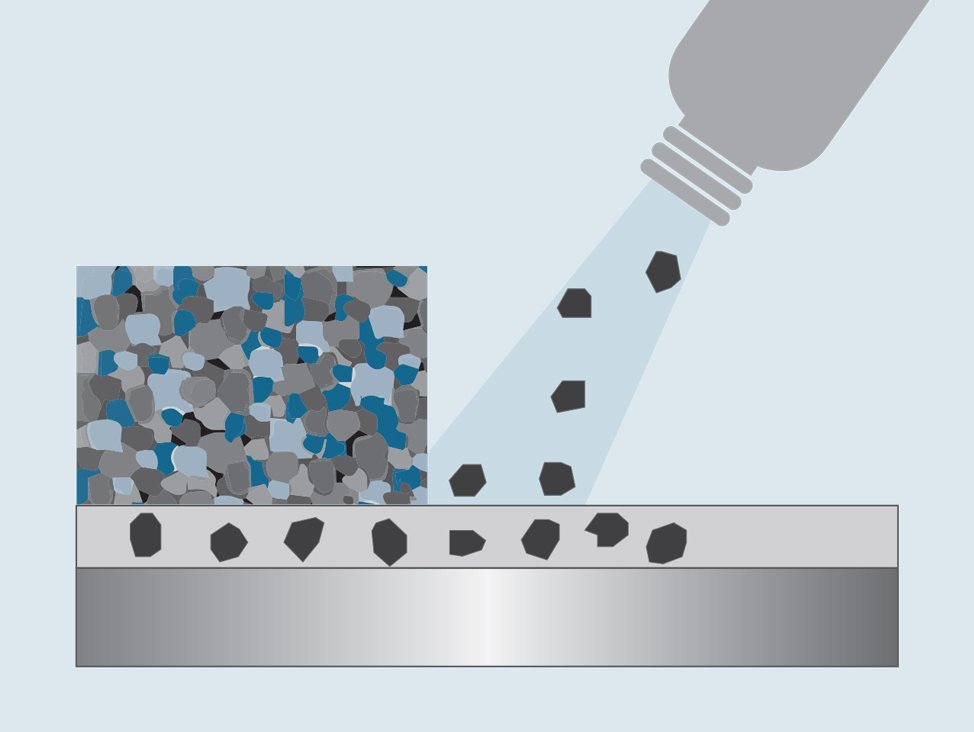

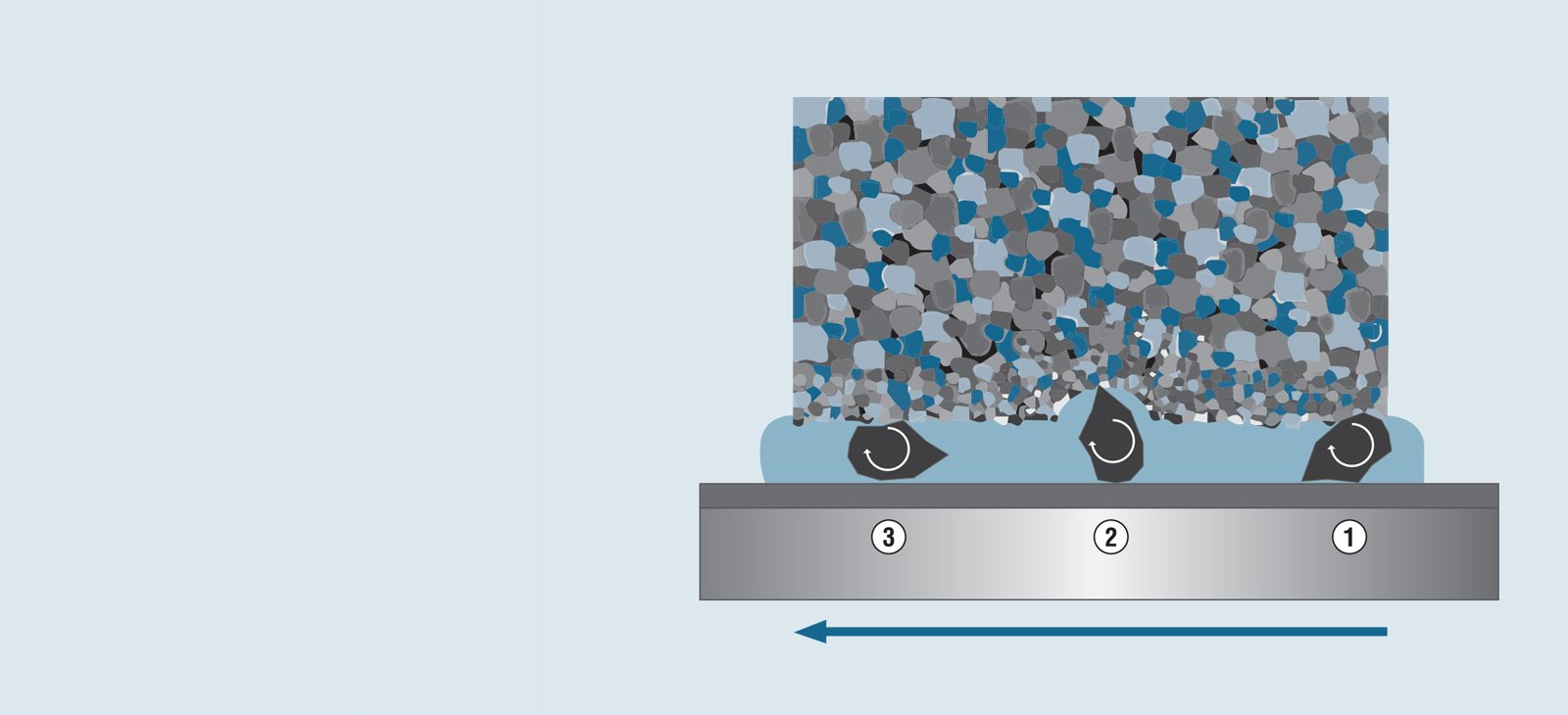

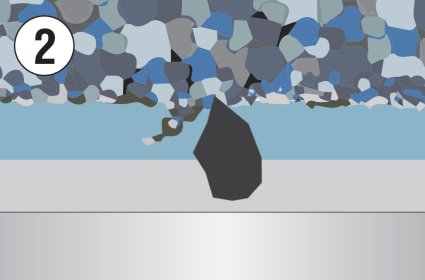

Depending on the type of material and the grinding/polishing disk used for preparation, the amounts of lubrication and cooling have to be balanced. Generally, it can be said that soft materials require high amounts of lubricant to avoid damage, but only small amounts of abrasive as there is very little wear on the abrasive. Hard materials require less lubricant but higher amounts of abrasive, due to faster wear. The amount of lubricant has to be adjusted correctly to get the best result.

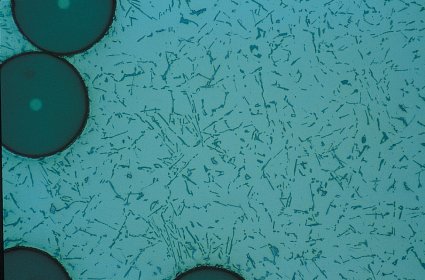

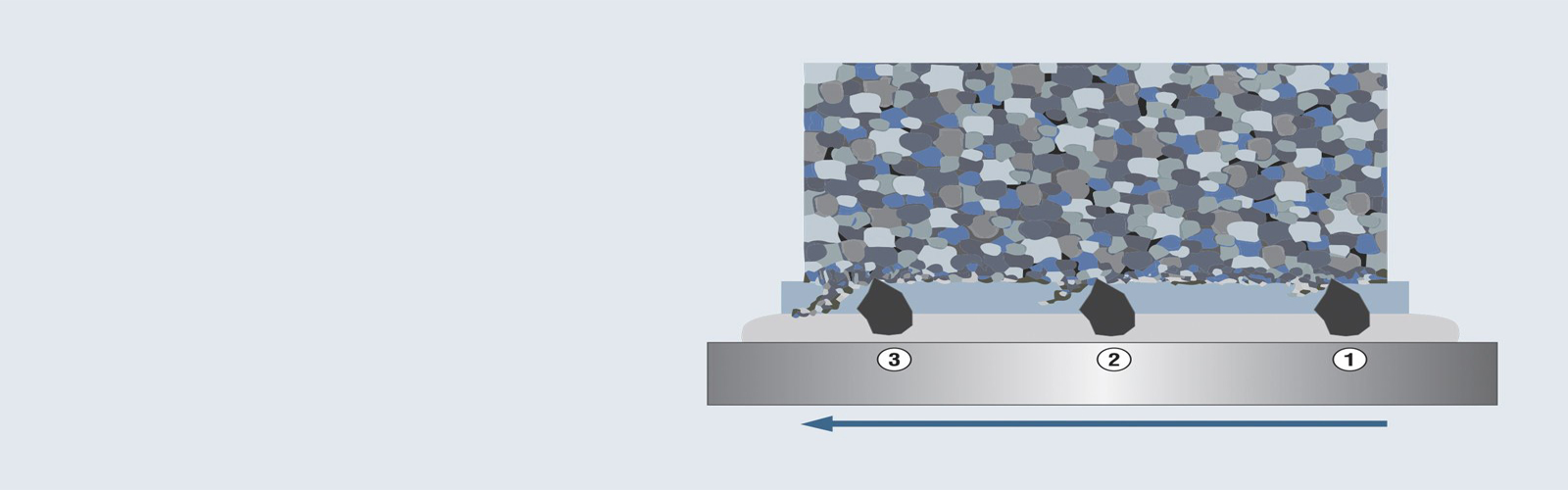

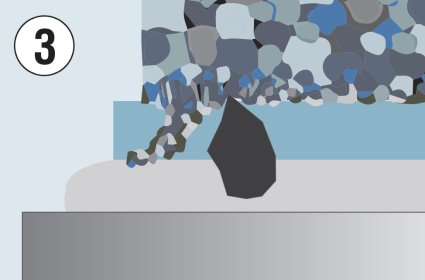

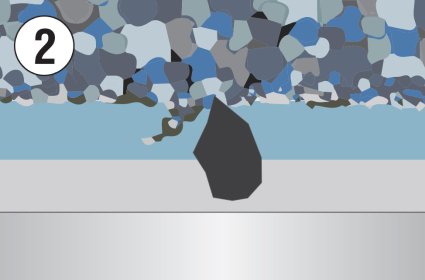

The polishing cloth should be moist, not wet. Excess lubricant will flush the abrasive from the disk and remain as a thick layer between the specimen and disk, thus reducing material removal to a minimum.

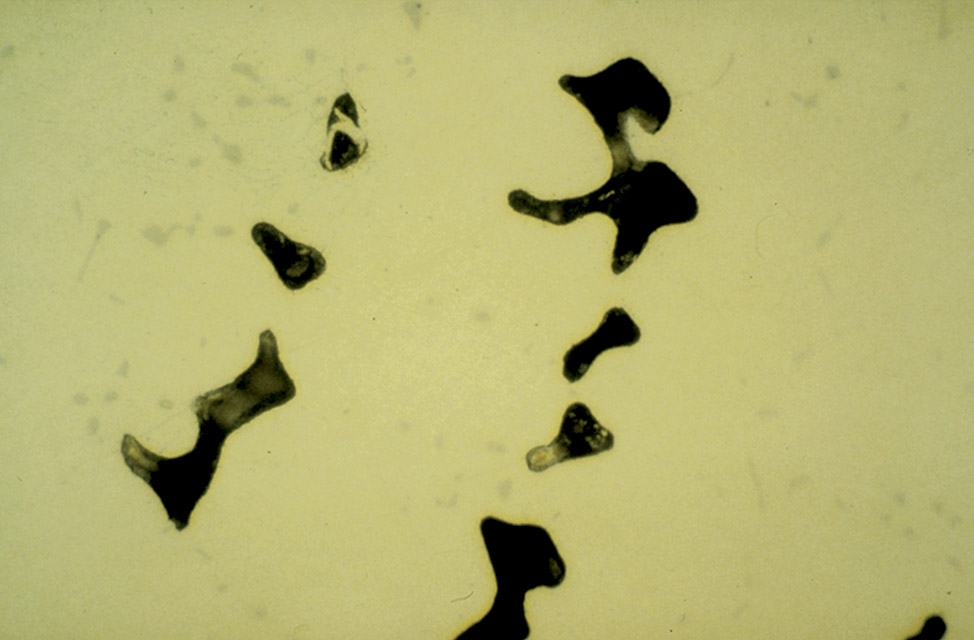

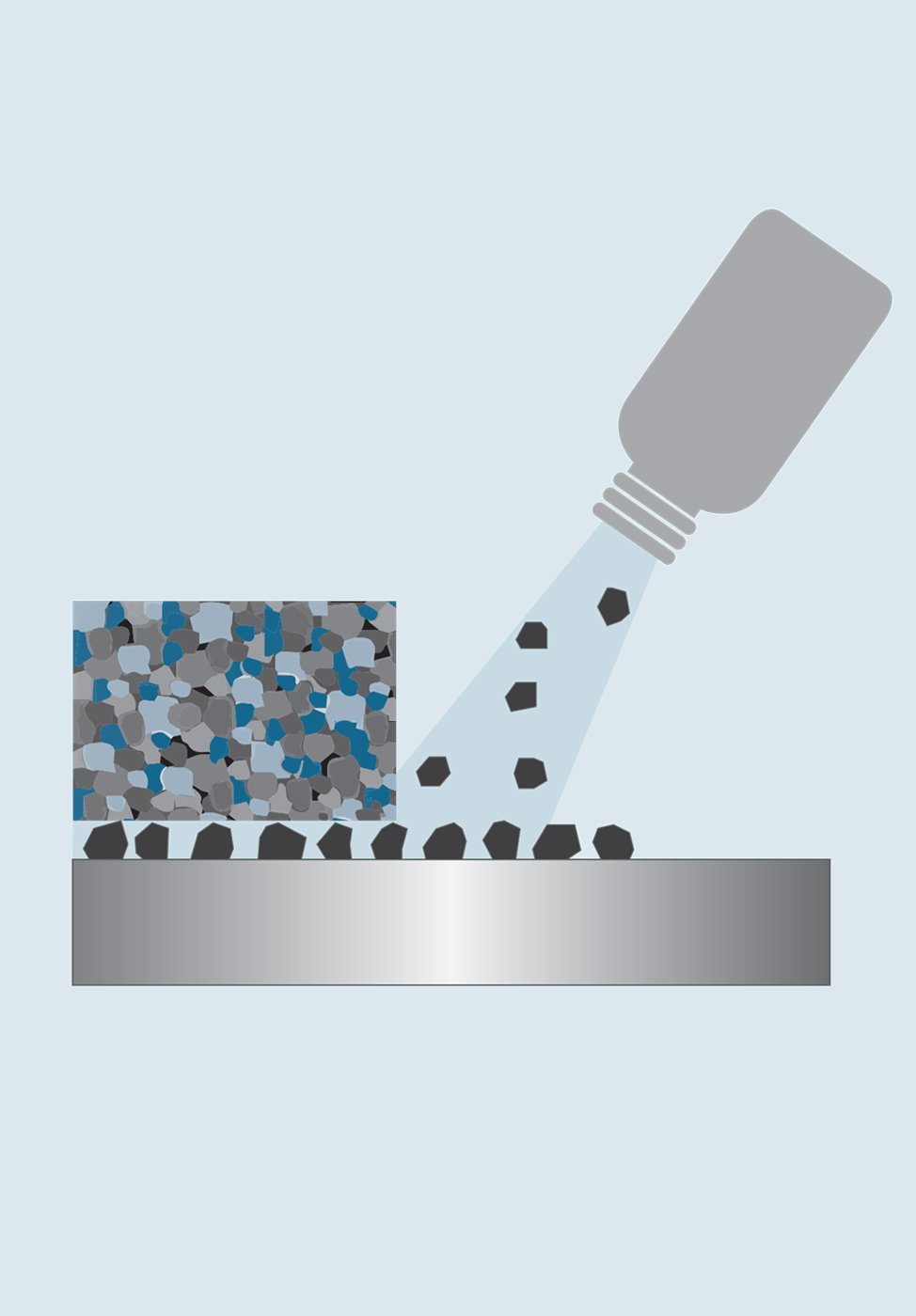

For two-in-one diamond suspensions, lubrication and cooling liquids are included and balanced in the bottle to optimize the relevant preparation method.