HARDNESS TESTING

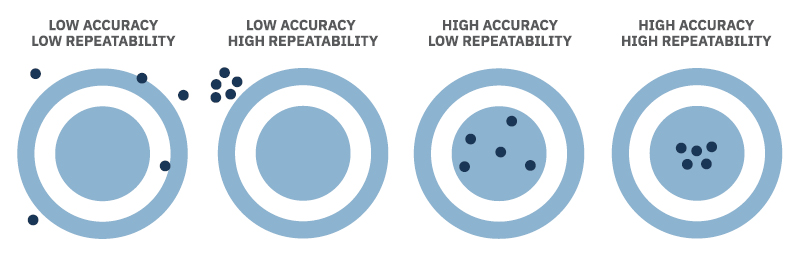

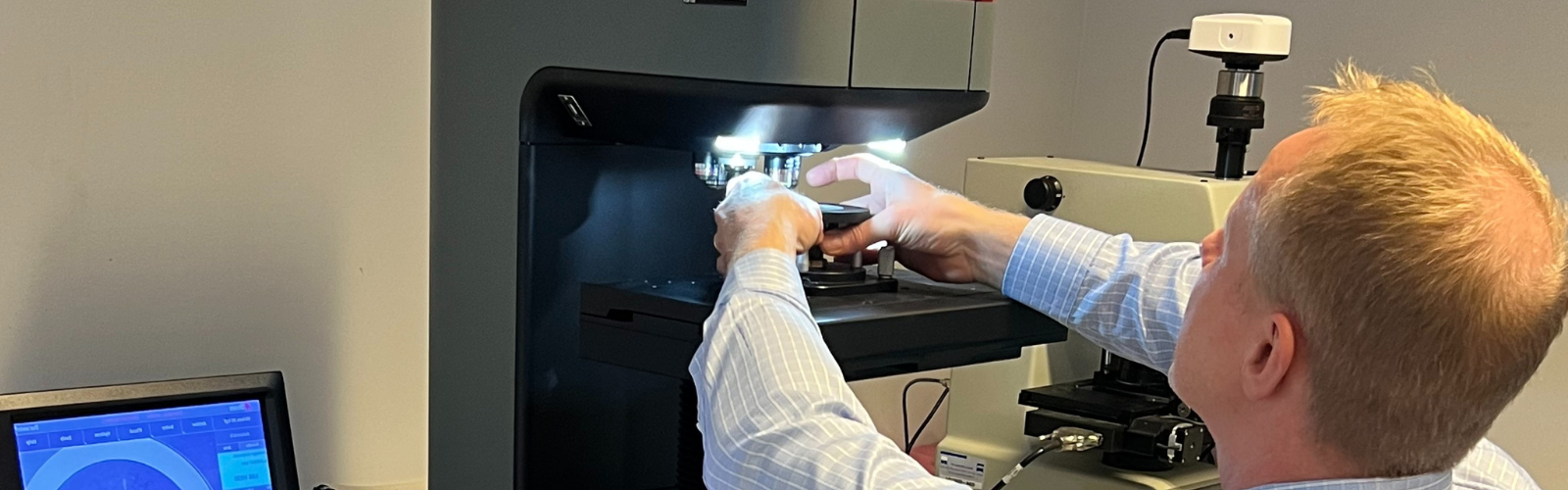

Explore the world of hardness testing, where you can learn about the principles of hardness testing for metals and materials, including industry standards, theoretical background, the main hardness testing methods, and practical application tips.

Whether you are a professional in hardness testing or just starting out, you'll find useful resources, including free downloads of posters and application notes, as well as access to webinars, to support your testing and material analysis needs.

To delve deeper into the details of hardness testing, explore our comprehensive Hardness Tester brochure for more information.

Download brochure