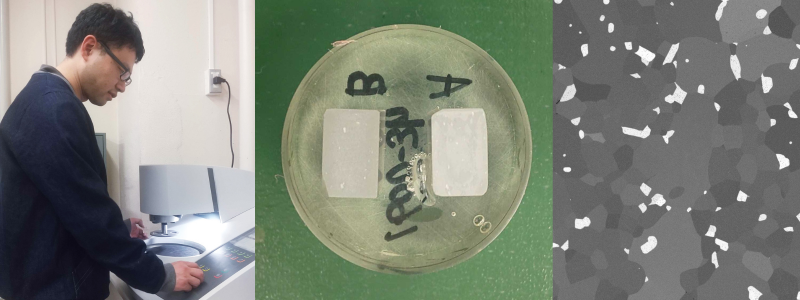

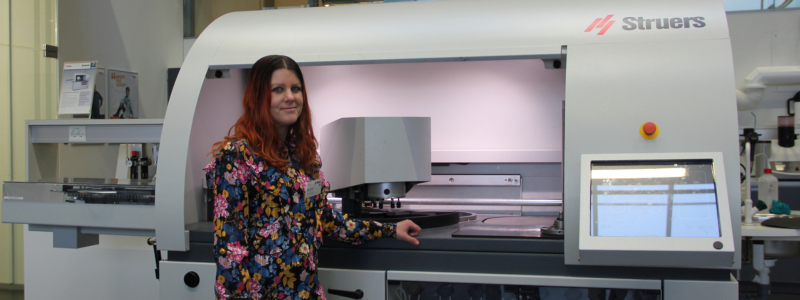

Meet our customers

Be inspired by industries worldwide using Struers solutions to meet their metallographic needs and preparation challenges. Take a deeper dive to understand their challenges and how our experts and preparation solutions helped to maximize accuracy, efficiency, and reproducibility.

Below you will find a selection of business cases where our equipment, solutions, and knowledge training have been used to improve the preparation process in various industries.