Discotom facts

- OptiFeed – intelligent feed control

- AxioWash* (Automatic cleaning)

- ExciCut for very hard materials

- MultiCut (Serial cutting – results in a number of slices.)

- Method Database

- Cut-off wheel database

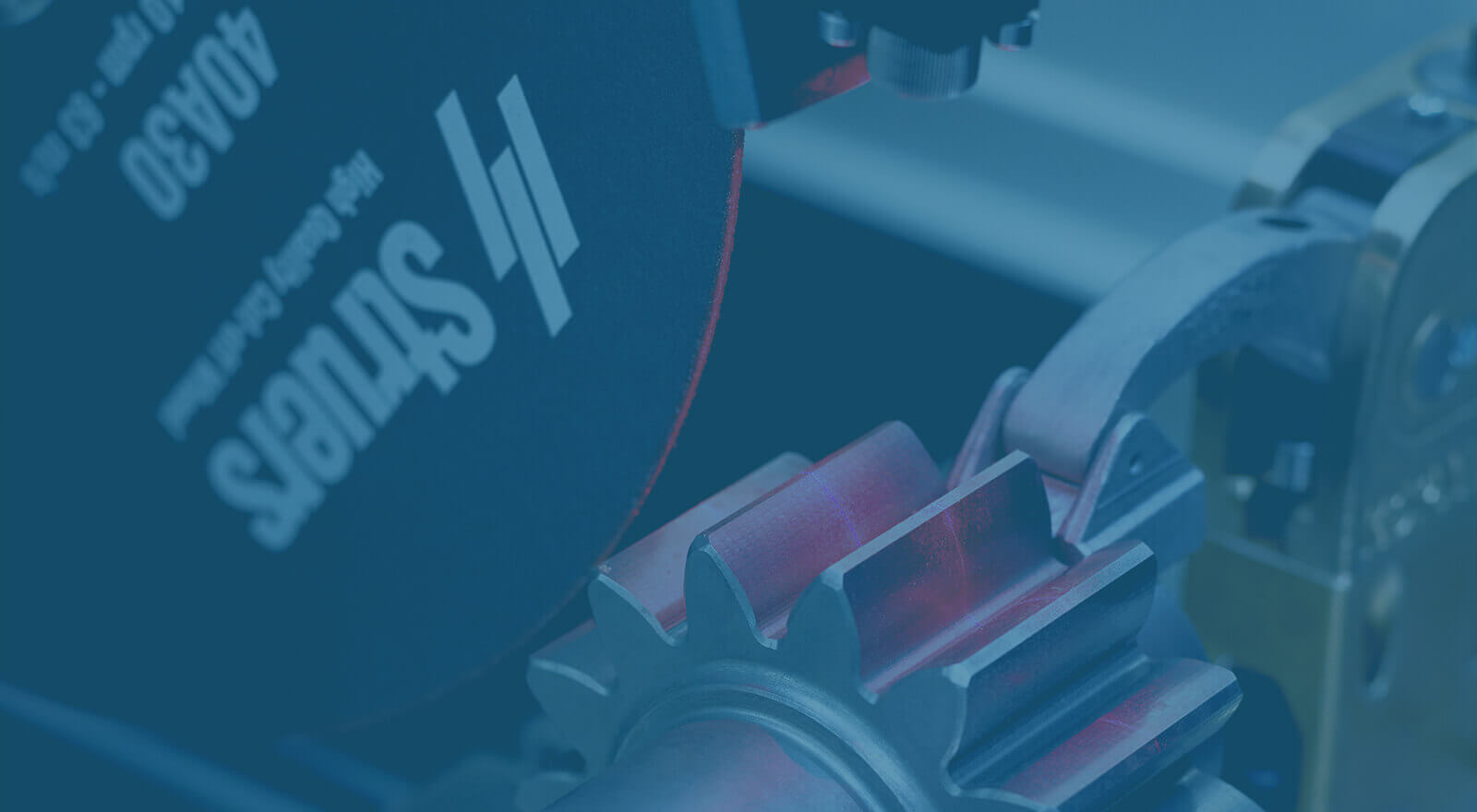

Discotom-10 and Discotom-100 are versatile tabletop cut-off machines, designed to give you a cost-efficient opportunity to expand your cutting capabilities and streamline your cutting processes. Spacious, versatile, and easy to use, Discotom-100 and Discotom-10 deliver exceptional cutting flexibility, with more cutting options that let you clamp and cut all types of workpieces efficiently, with less effort and minimum deformation.

Fast and accurate

Newest cutting technologies, such as intelligent speed adjustment, deliver fast and accurate cuts. Select the hardness of the material to be cut, and the machine automatically sets the correct speed.

Exceptional versatility

When the wheel is clogged by removed material, it is possible to choose between the automatic Direct Cutting mode which uses a constant feed speed or Impact Cutting . The ExciCut manual cutting mode is used to section harder and larger workpieces. The automatic X-table option allows the user to access MultiCut to cut slices of the same or varying thickness, or cut precisely in specified positions.

Time-saving

The multifunction knob makes setting cutting process parameters quick and easy. Automatic speed setting saves time and lets the user apply the same wheel for different materials to avoid time-consuming wheel changes. Fast changing between manual and automatic cutting is enabled by the motorized cutting arm locking system, and the icon-based color display gives a complete overview of all the information you need.

KEY FEATURES THAT ENABLE GREATER VERSATILITY AND PRODUCTIVITY

-

All-in-one

Discotom-100/-10 are versatile automatic and manual cut-off machines, all in one.

All-in-one

-

Largest cutting table in its class

Measuring 620 x 270 mm, the Discotom cutting table is almost twice the size of competing machines. A large selection of clamping tools for the 10 mm T-slots make it easy to clamp workpieces of almost any shape or size.

Largest cutting table in its class

-

Unmatched user friendliness

The icon-based user interface, the easy-to-operate multifunction knob and joystick, the automatic cleaning program AxioWash*, and the electric brake ensure easy operation and reduce the risk for user errors.

Unmatched user friendliness

-

Latest cutting technologies

Discotom-100/-10 offers automatic and manual cutting capabilities. OptiFeed ensures the correct feed speed without compromising cut quality or wheel economy. Combine the manual cutting mode with ExciCut to allow faster cutting of even very hard materials.

Latest cutting technologies

-

Automatic X-table

Use one of the four MultiCut functions of the optional automatic X-table to cut slices of the same or varying thicknesses, or cut your workpiece precisely in pre-defined positions.

Automatic X-table

-

AxioWash*

Struers' patented* automatic chamber cleaning function that can be used every day to keep the machine in optimal working condition.* AxioWash is protected under EP Pat no. 1965947.

AxioWash*

-

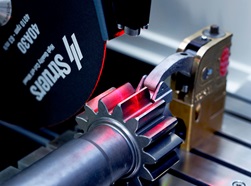

ExciCut

Speeds up manual cutting of hard materials.

ExciCut

-

Method Database

Stores up to 20 cutting methods for quick and easy retrieval.

Method Database

-

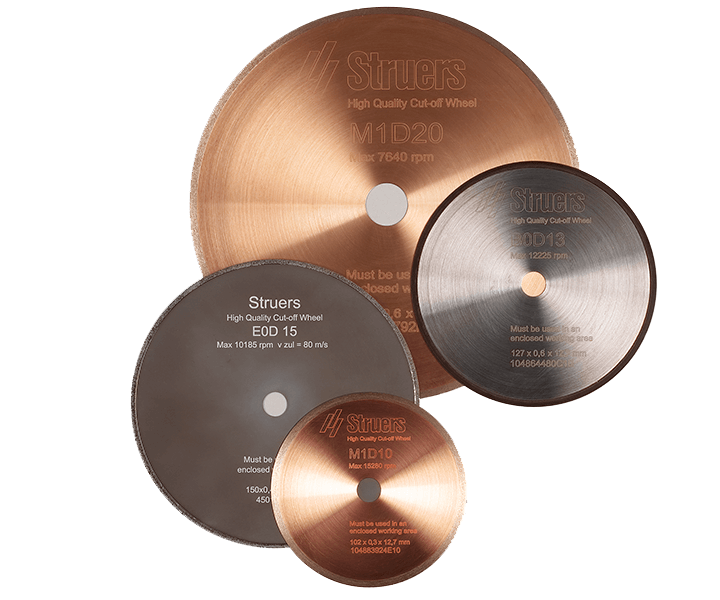

Cut-off wheel database

All Struers’ cutoff wheels are stored with recommended rotational speed and wheel thickness.

Cut-off wheel database

-

Intelligent speed adjustment

Ensures the correct speed on Discotom-100 for a given cut-off wheel in combination with the hardness of the material. The same wheel can be used for different materials without sacrificing the quality of the cut.

Intelligent speed adjustment

-

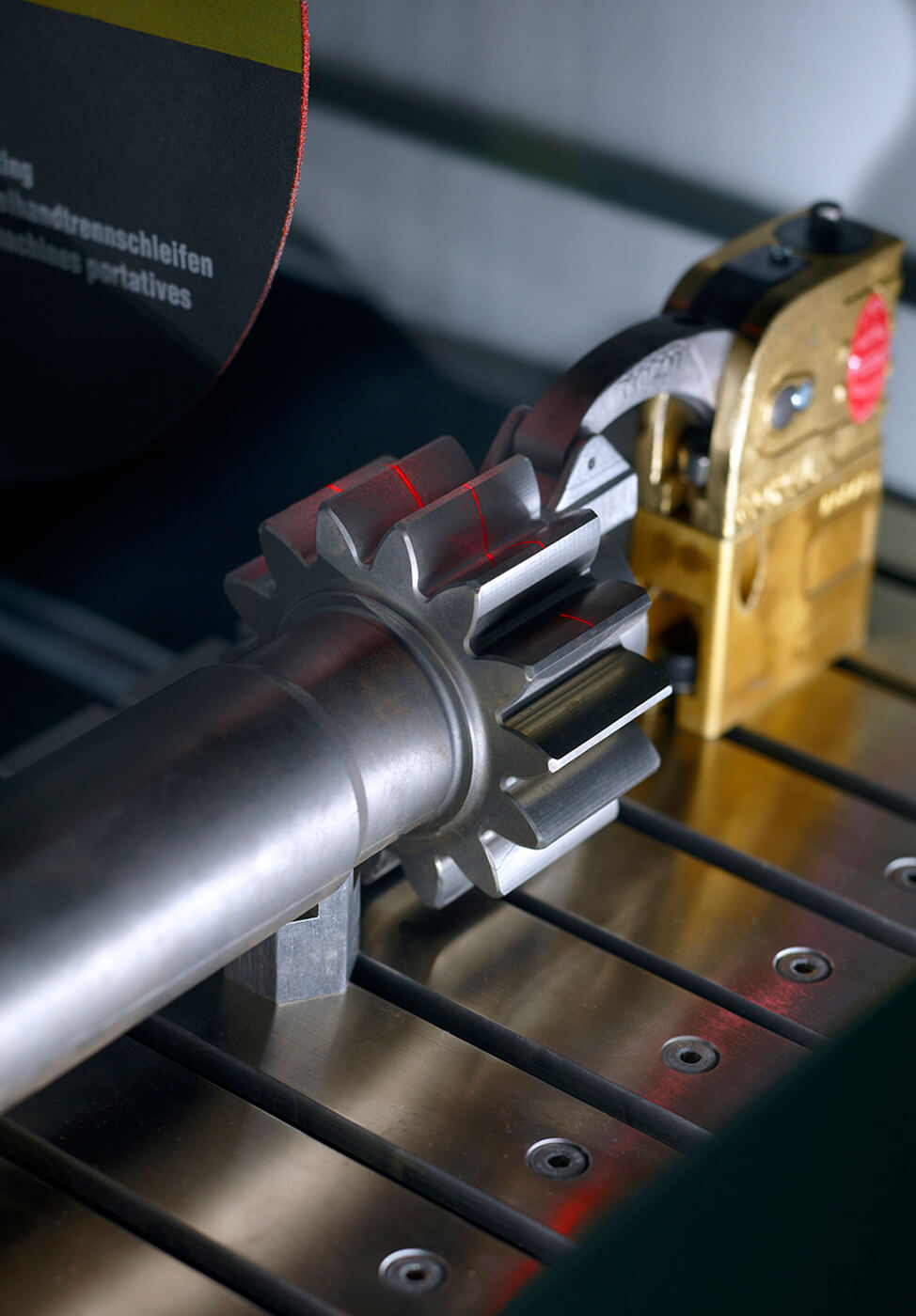

Line laser

The optional line laser enables precise alignment of the workpiece without having to move the cut-off wheel.

Line laser

-

Cut-off wheel size

300 mm. (Discotom-100) and 250 mm. (Discotom-10) diameters.

Cut-off wheel size

-

Safety features

Enhanced safety feature that if your sample isn't clamped correctly, the direction of the blade rotating ensures that the sample is directed to the cutting table. The safety chain catch (interlock and magnetic switch) prevents the cut-off wheel from starting while the hood is open and ensures the operator can't open the hood until the cut-off wheel stops spinning. The safety chain switch ensures that two handed operation need to be used for the X-Y table movement when the hood is open.

Safety features

Facts

Model types

Discotom is available in two variations, see specifications for details.

Discotom-100

Discotom-100 with fixed table

Automatic cut-off machine with variable spindle speed and variable automatic feed. 4.0 kW motor. For 300 mm (12") cut-off wheels. Cutting table with 10 mm T-slots. Recirculation Cooling Unit and clamping tools are ordered separately. Optional table unit can be used.

Discotom-100 with automatic X-table

Automatic cut-off machine with automatic X-table, variable spindle speed, and variable automatic feed. 4.0 kW motor. For 300 mm (12") cut-off wheels. Cutting table with 10 mm T-slots. Recirculation cooling unit and clamping tools are ordered separately. Optional table unit can be used.

Discotom-10

Discotom-10 with fixed table

Automatic cut-off machine with fixed spindle speed (2,850 rpm) and variable automatic feed. 2.2 kW

motor. For 250 mm (10") cut-off wheels. Cutting table with 10 mm T-slots. Recirculation Cooling Unit

and clamping tools are ordered separately. Optional table unit can be used.

Discotom-10 with automatic X-table

Automatic cut-off machine with automatic X-table, fixed spindle speed (2,850 rpm) and variable automatic

feed. 2.2 kW motor. For 250 mm (10") cut-off wheels. Cutting table with 10 mm T-slots. Recirculation

cooling unit and clamping tools are ordered separately. Optional table unit can be used.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

Discotom-100/-10 Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download technical data sheetGet Your Brochure for Discotom

Get the full introduction, descriptive visuals, and key feature descriptions to assist you in deciding on your choice of equipment.

• Explanatory photos

• Key feature descriptions

• Technical Data Sheet

Cutting consumables

-

Abrasive cut-off wheels

Extremely hard ferrous metal (500 < HV < 1400).

Go to webshop Contact sales -

Abrasive cut-off wheels

Very hard ferrous metal (400 < HV < 800).

Go to webshop Contact sales -

Abrasive cut-off wheels

Hard Ferrous metal (275 < HV < 750).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium hard ferrous metal (200 < HV < 550).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium soft ferrous metal (100 < HV < 500).

Go to webshop Contact sales -

Abrasive cut-off wheels

Soft ferrous metal (75 < HV < 375).

Go to webshop Contact sales -

Diamond cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

CBN cut-off wheels

For materials with HV 500-2400.

Go to webshop -

Additives for cutting

For recirculation, cooling and cleaning.

Go to webshop Contact sales -

+

-

−

Correct preparation solutions

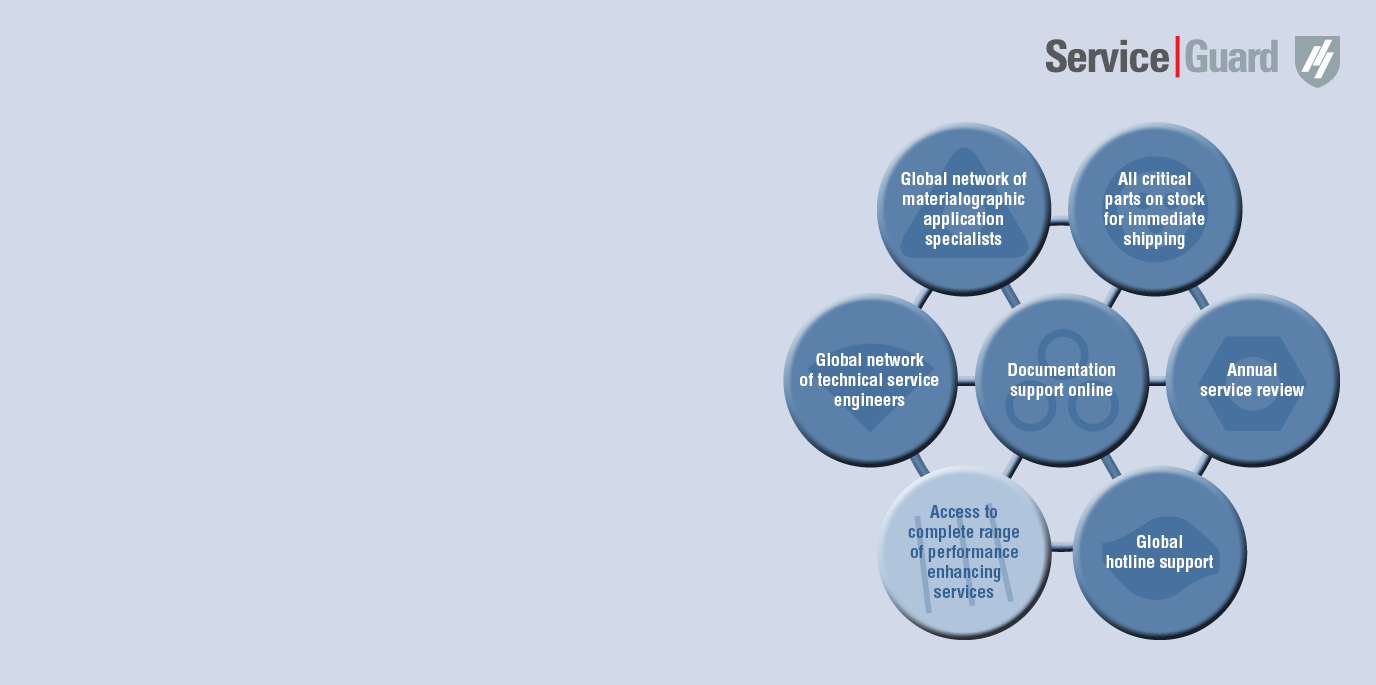

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer