Xmatic facts

- Maximum reproducibility and efficiency with full automation

- Improve workplace safety with minimal operator intervention

- Eliminate human error and process variation

- High throughput

- Support process standardization

- Full process documentation

- Multiple cleaning options

- Plug and prepare, with minimal training needed

Xmatic is a fully automated, end-to-end grinding and polishing solution. It has been designed for labs that need the very best in terms of reproducibility, throughput, process standardization, and ease-of-use.

HOW DOES XMATIC SUPPORT YOUR GRINDING AND POLISHING PROCESS?

Maximum reproducibility

By minimizing the risk of human error, Xmatic significantly improves reproducibility. Setup is quick and simple, then Xmatic does the rest by automatically setting up parameters such as force. The result is greater reproducibility, less consumables waste, and optimized throughput, which means greater certainty.Process standardization

Xmatic gives you full documentation data, including the number of specimen holders that it runs, methods used, consumables consumption, and operating times. This enables you to standardize your process for greater reproducibility and efficiency.Higher throughput

Xmatic has rapid and simultaneous mechanical movements that reduce process time, including fast cleaning programs and up to 8 specimen holders that can be loaded at any time. Throughput is further increased by minimizing human error and potential rework.Ease of use

Xmatic has been designed with simplicity, flexibility, and user wellbeing in mind. Featuring an intuitive user experience with ‘embodiment’, a new bottle concept with Easy connectors for fast, spillage-free consumable change, and multiple automated features that minimize the need for operator intervention, Xmatic is easy to set up and use with minimal training.Be inspired by our customers

One of our customers, NCS (Shenyang) Testing Technology Co., needed our support to improve their preparation process. In our case story you can dive into the challenge, the solution, and the results to learn how we’ve helped customers overcome the sample preparation challenges—improving accuracy, efficiency, repeatability, and skills through knowledge. Get inspired by real examples and proven results.Read more

From loading the machine to finished specimen

It takes around 5 minutes for a lab technician to set up Xmatic with consumables and insert 8 specimen holders, all with their own method. Xmatic then does the rest – automatically – while the technician works on other tasks.

This video shows Xmatic performing the entire grinding and polishing process, including:

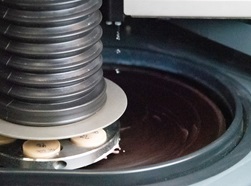

· High removal plane grinding and fine grinding

· Pre-dosing of preparation surfaces

· Polishing

· High pressure cleaning and spin drying between preparation steps

· Final cleaning and drying of specimens

KEY FEATURES FOR MAXIMUM REPRODUCIBILITY AND PROCESS EFFICIENCY

-

Optimize lab space

Xmatic has been designed to minimize the floor space it requires, for example using a vertical conveyor to optimize its footprint. However, for labs where space is particularly limited, Xmatic also comes in a smaller model, Xmatic Compact, that does not include a high-speed plane grinding station. Instead, plane grinding can be done on a MD grinding and polishing station, with a speed up to 600 rpm.

Optimize lab space

-

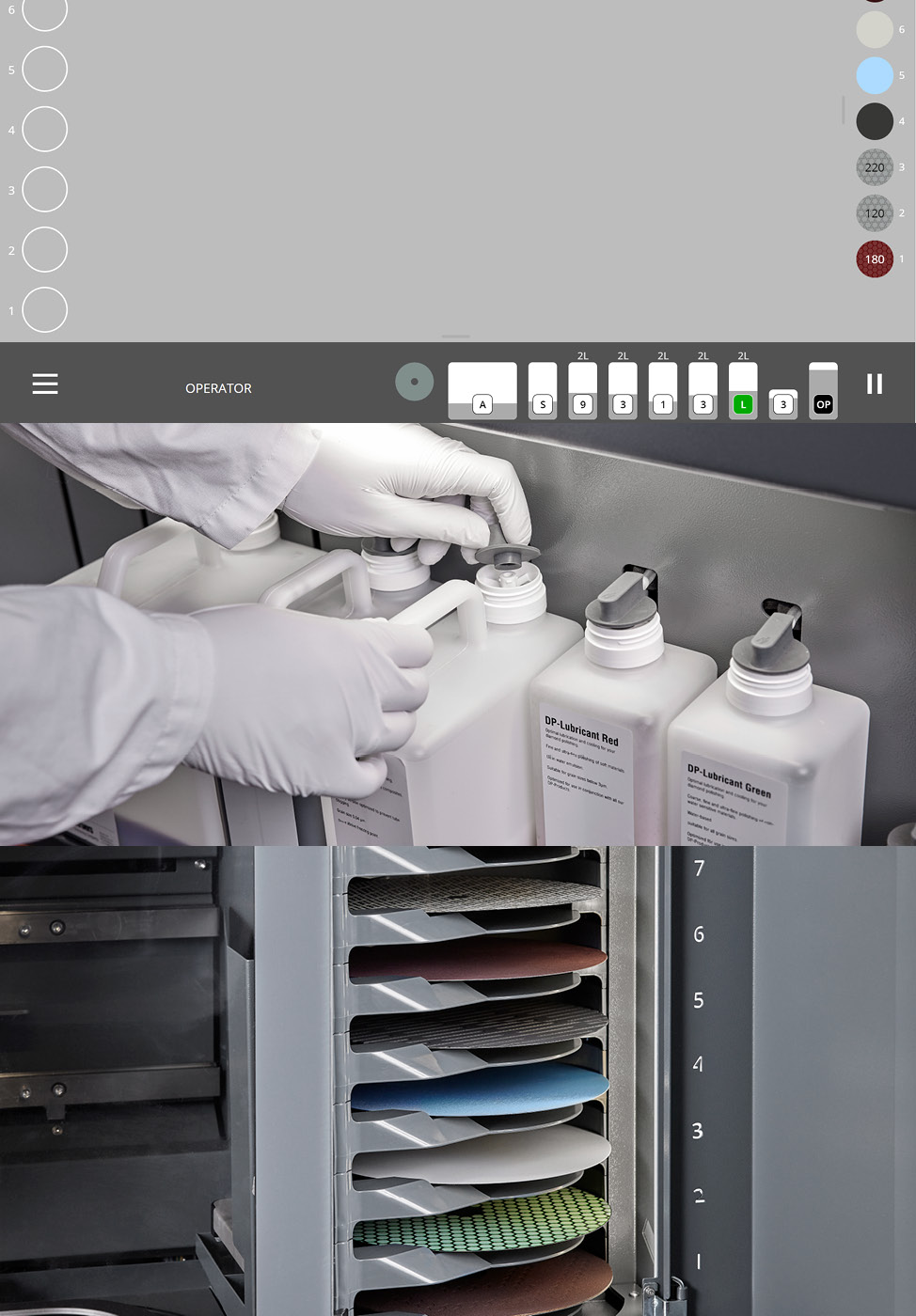

Intuitive user interface

The entire user experience is simple and intuitive, requiring less training to operate. A redesigned user interface gives a complete representation of the machine, with a vertical conveyor to the left, consumables on the bottom, and cloths to the right (so-called ‘embodiment’).

Intuitive user interface

-

Automatic detection of consumables

Codes on each consumable bottle or MD surface give Xmatic the data it needs, which eliminates entering incorrect information and saves time when setting up the system. Xmatic can also detect what µm size it has previously used on each MD polishing surface, which eliminates risks of contamination.

Automatic detection of consumables

-

Automatic tube cleaning

A special cleaning program for flushing the tubes means that Xmatic can help you to avoid contamination when changing suspension and lubricant. The machine can recognize if the tube has not been cleaned and will alert the operator if changing to a different µm size, without asking the system to clean.

Automatic tube cleaning

-

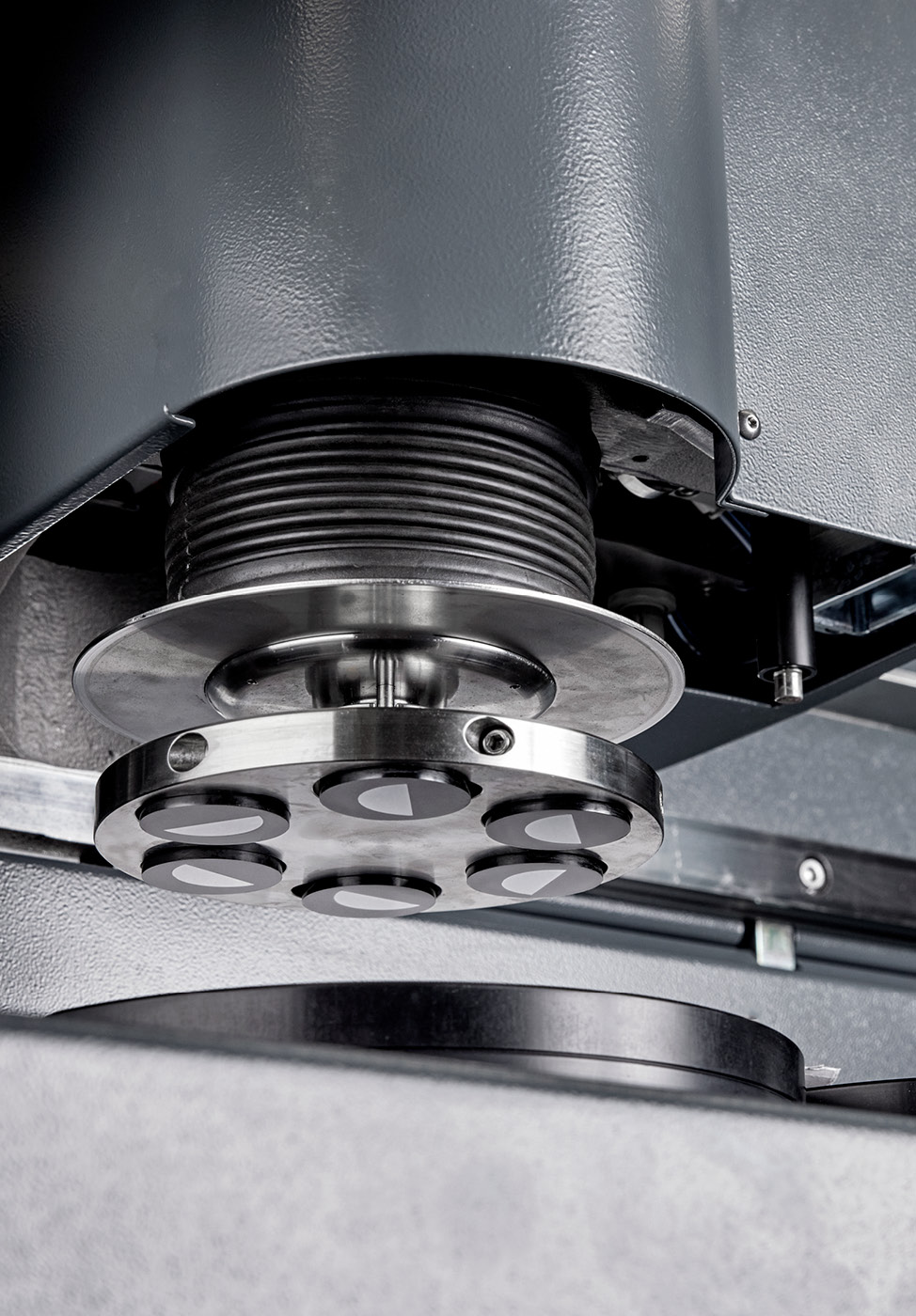

Dressing of MD grinding surfaces

Xmatic is equipped with two dressers that fit different surfaces. The frequency can be set to keep the removal rate of a grinding surface. This means you do not need to supervise the surface performance or manually dress each surface.

Dressing of MD grinding surfaces

-

Complete cleaning and drying

Xmatic features different cleaning options. A high-pressure cleaning system with optimal nozzle positioning and improved water pressure. Ultrasonic cleaning is also an option. Drying is done by spinning the specimen holder leaving you with perfectly clean and dry specimens.

Complete cleaning and drying

-

Pre-cleaning

A pre-clean step can be added for specimens prepared with e.g. oil-based suspension/lubricants using a dedicated MD-Nap cloth adding soap and water.

Pre-cleaning

-

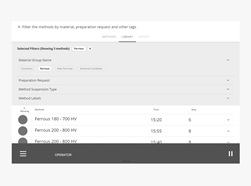

Easy filtering of methods

An improved filtering functionality makes it easy to find and select a method in Struers’ vast method database.

Easy filtering of methods

-

2 sets of methods

Two separate sets of Struers methods are available. One set of methods for Xmatic includes a high removal grinding station and one set of methods for Xmatic Compact that does not include a high removal grinding station.

2 sets of methods

-

Inspect functionality

Xmatic allows you to stop the process at any given stage to inspect your specimens. When returning the specimen holder to the vertical conveyor, the machine will ask if it should continue from the process step it stopped or start from the beginning.

Inspect functionality

-

Step selection

Xmatic enables you to choose which steps to run in a method to give you full flexibility. Just choose which steps you want to run.

Step selection

-

Accurate dosing pumps

Xmatic features a new type of pump system that is controlled in very small and precise steps, no matter the viscosity of the fluid. This ensures your process is reproducible, with no dosing variation.

Accurate dosing pumps

-

High capacity on disc and in specimen holder

Xmatic is compatible with disc sizes either 250 or 300 mm dia. and specimen holders either 140 or 160 mm dia. A larger disc size gives you a larger preparation area and supports the processing of larger specimens.

High capacity on disc and in specimen holder

-

Closed chamber

Everything is housed within a closed chamber, which means there is less human interaction and less risk to health and safety. This helps workers to feel more comfortable in the lab environment, reducing absenteeism.

Closed chamber

-

Force adjustment according to number of specimens

Xmatic can automatically adjust the force in the method according to the number of specimens in the specimen holder. This eliminates the need for you to calculate the force yourself. It also reduces the number of methods required in the method database. Just select the number of specimens in the specimen holder by clicking on the icon.

Force adjustment according to number of specimens

-

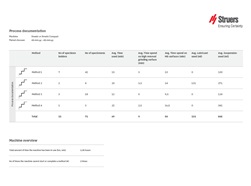

Data reporting

Xmatic creates log files that can help you verify and improve the process, store records, and monitor for maintenance. The machine registers the number of specimen holders, the methods and consumables used, and more.

Data reporting

-

Automatic cloth run-in

Xmatic performs an automatic run-in process for new polishing surfaces to check whether pre-dosing should happen prior to starting. This removes the need for human attention when running in a new polishing cloth.

Automatic cloth run-in

-

Load up to 8 specimen holders

You can load up to 8 specimen holders at a time and allocate the same or different methods to each specimen holder. The order they should be processed is selected by clicking on the icons.

Load up to 8 specimen holders

-

Changing suspension and lubricant

When a consumable is inserted, Xmatic automatically recognizes the consumable by a unique data matrix code. If you run out of suspension or lubricant, you can change to a new bottle containing the same without cleaning the tubes. If you change to a different suspension or lubricant without asking to clean the tubes, Xmatic warns you and asks you to clean the tube or proceed without cleaning.

Changing suspension and lubricant

Facts

Model types

Xmatic is available in two variations, see specifications for details.

Reproducibility that only automation can deliver

Xmatic has been designed to help save space in your lab, with a footprint of w: 242 cm / 95" and D: 75 cm / 29". The setup comes with a high removal grinding station and MD grinding and polishing station along with a vertical conveyor to load your specimen holders. You can choose a MD disc size of 250 mm / 10" or 300 mm / 12" depending on your requirements. Recirculation is standard on the high removal grinding station and optional on the MD grinding and polishing station. Cleaning can either be high-pressure cleaning, high-pressure cleaning including alcohol, or high-pressure cleaning and ultrasonic cleaning.

Optimize lab space

If your lab floor space is limited, Xmatic Compact comes with or without the vertical conveyor, giving a footprint of w: 149 cm / 58" and D: 75 cm / 29". This includes an MD grinding and polishing station with speed up to 600 rpm for plane grinding on MD surfaces, with either a 250 mm / 10" or 300 mm / 12" dia. MD disc. Recirculation is optional, and cleaning can either be high-pressure cleaning including alcohol or high-pressure cleaning and ultrasonic cleaning.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

Xmatic / Xmatic Compact Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical Data SheetGet your brochure for Xmatic

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

Find the right accessories for your Xmatic

Increase the efficiency of your process and improve the reliability of your result with our grinding and polishing accessories. We offer a full range of specimen holders, mover plates, leveling devices, and preparation discs.

Download our accessories overview sheetGrinding & Polishing consumables

-

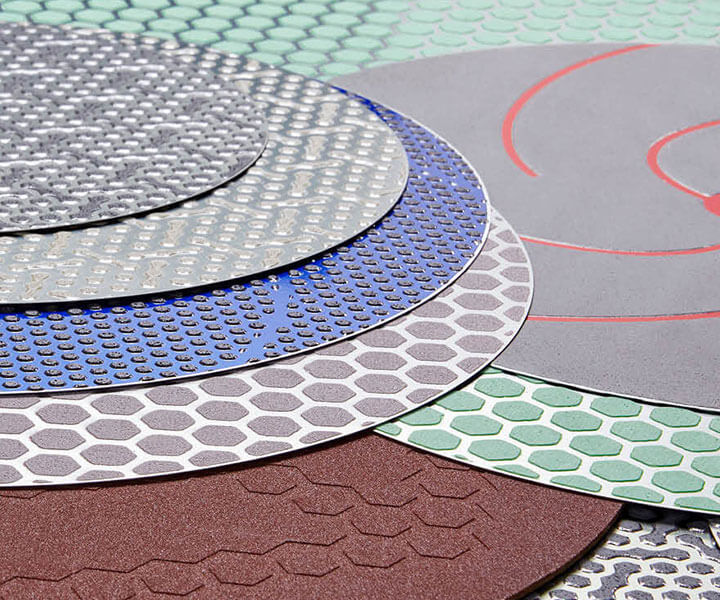

MD Grinding

For plane and fine grinding with virtually no artifacts

Read more Contact sales -

DiaPro

All-in-one diamond solution optimized for a specific polishing cloth

Read more Contact sales -

DiaDuo-2

All-in-one diamond solution

Read more Contact sales -

Polishing cloths

For any material and preparation goal

Read more Contact sales -

DP-Products

Diamond suspensions in a wide variety of grain sizes and formats

Read more Contact sales -

DP-Lubricants

For accurate cooling and lubrication while polishing

Read more Contact sales -

Oxide Polishing

When no scratches and deformation is required

Read more Contact sales -

+

-

−

Related products

AbraPlan

- Ultra-fast for up to 90% faster plane grinding

- High-capacity, and controlled material removal

- Powerful performance, with exceptional stability

The strongest dedicated high-speed plane grinding machine on the market, AbraPlan is ideal for high throughput labs that need fast...

AbraPol

- High capacity for large specimens

- Powerful and fast preparation

- Adjustable dosing units

AbraPol-30 is an advanced, semi-automatic machine for grinding and polishing of specimens in specimen holders. Double dosing of di...

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

References

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer

The Tegramin-25 and CitoPress-20 mean considerably easier and shorter workflows in the lab, and can be recommended.Stahlhärterei Haupt GmbH: Arkadiusz Bytner Labor and Quality Management Officer

“Struers Tegramin-30 enables us to achieve specimens free of scratches for improved evaluation, and saves us time and labor when compared to our former manual preparation with aluminum oxide.”Federal-Mogul Powertrain Mark Gibbins Materials Tester in Metal Technology