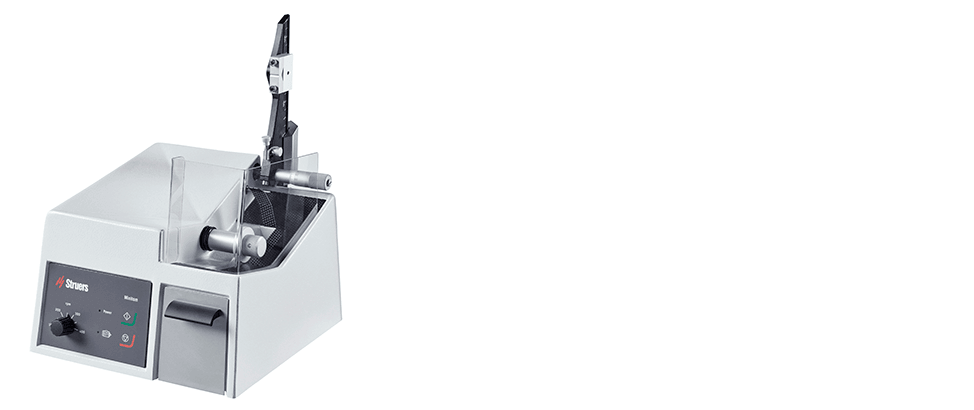

Minitom

- Workpieces up to 30 x 40 mm

- High-precision tabletop machine

- Low speed protects against heat deformation

- Accuracy of +0.01 mm

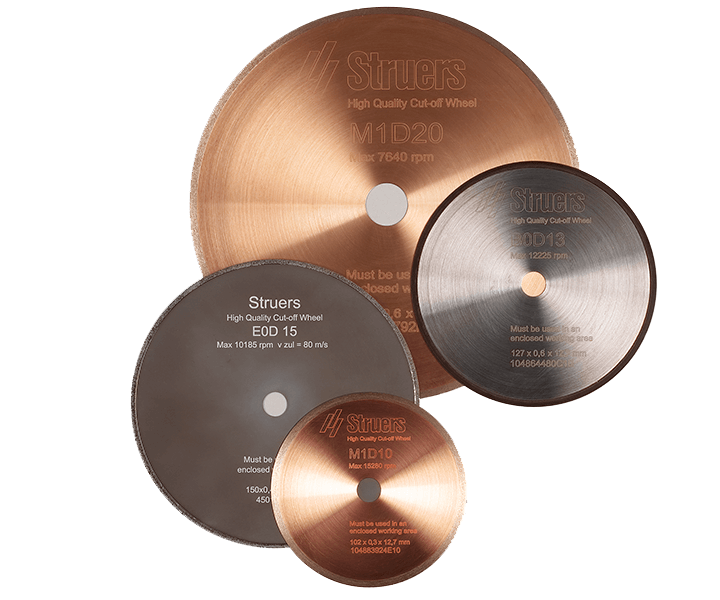

- 75-125 mm (3-5’’) CBN and diamond cut-off wheels

A small, low-speed, automatic precision cutting machine for sectioning delicate materialographic workpieces that can’t tolerate the heat generated by high-speed cutting. The gravity feed design allows for sectioning of various material types, with high accuracy and reproducibility. Minitom is designed with speed and efficiency in mind. The simple design means it only takes a few minutes to setup a cut, and the machine can be set to stop automatically once the cut is done, giving you more time to work on other tasks.

Get a high-quality cut in delicate materials

With Minitom, you can section small and delicate materialographic workpieces that can’t tolerate the heat generated by high-speed cutting. Whatever type of material your work with, the gravity feed design enables you to section deformation-free samples with high reproducibility.

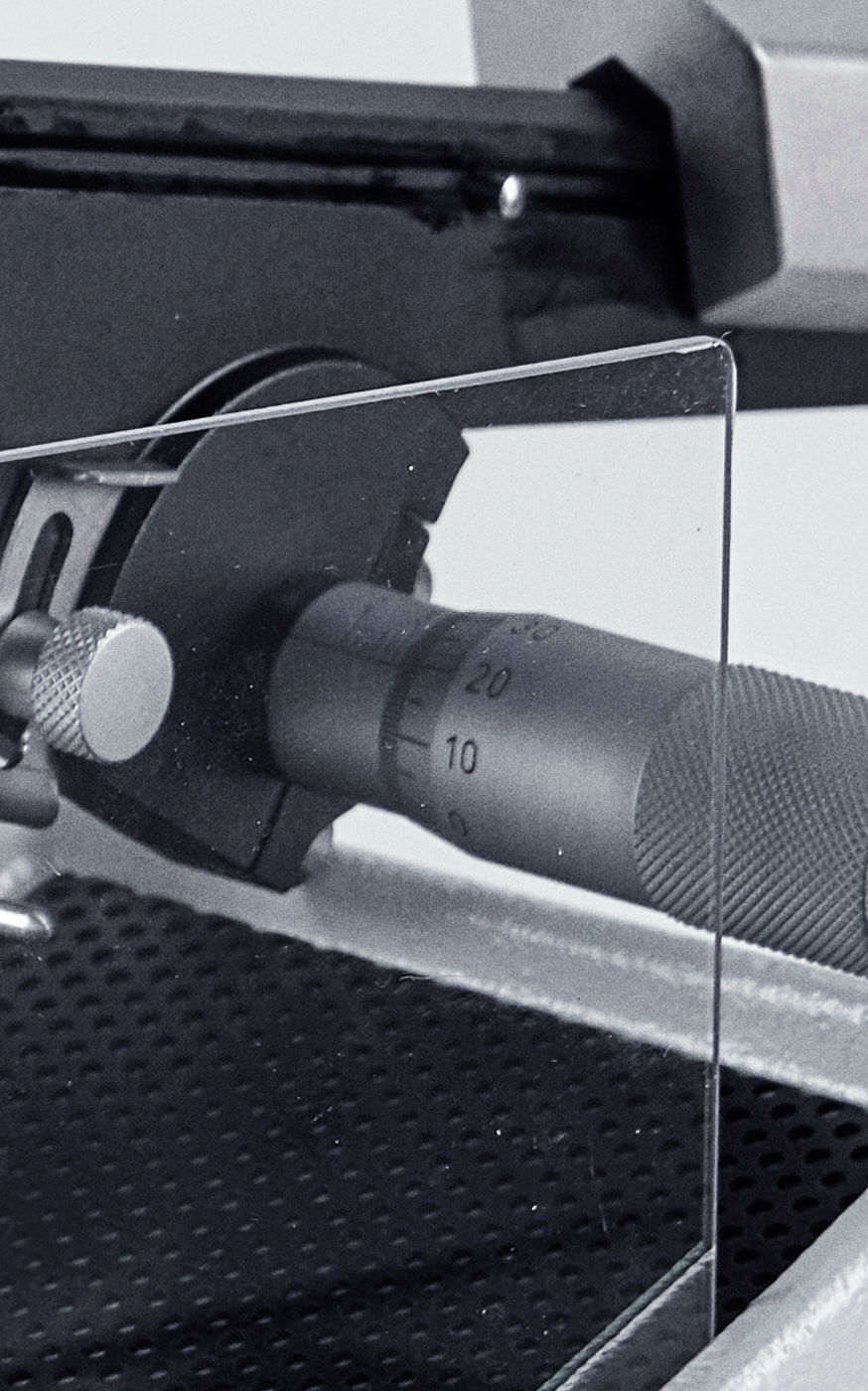

Work with extremely high accuracy and precision

Minitom enables you to section workpieces to an accuracy of +0.01 mm using the micrometer screw, making it ideal for small pieces that require high precision.

Work fast to increase your throughput and efficiency

Minitom is designed with simplicity in mind, enabling you to work fast. It only takes a few minutes to fix the workpiece and set the stop position, cutting pressure and cut-off wheel rotational speed – so you can cut more pieces in less time and increase overall efficiency.

See the additional features in the brochure

KEY FEATURES ENABLING PRECISION SECTIONING OF ALL TYPES OF SPECIMENS IN THE LAB

-

Movable specimen holder arm

This arm acts as a steelyard with two weights. One balances the specimen holder with the specimen; the other is used to set the exact cutting pressure. During cutting, the arm is guided down over the cut-off wheel using the pressure from the cutting weight.

Movable specimen holder arm

-

Constant speed, even at high loads

Select the required cut-off wheel rotational speed and the motor will ensure the speed remains constant, even at high loads. For extra protection against damage, the sectioning pressure can be selected independently from the weight of the workpiece.

Constant speed, even at high loads

-

Avoid thermal overload

The overload indicator gives a visual warning if the cutting procedure needs to be stopped. To protect the motor from overload, thermal overload protection switches off the motor if the heat gets too high.

Avoid thermal overload

-

Cutting stop setting

Minitom can be adjusted to stop sectioning at any stage of the operation (e.g. when the material is cut through) giving you more time to work on other tasks. Just set the task up and set Minitom running – then come back when the job is done.

Cutting stop setting

-

Cut-off wheel cooling tank

To help protect your sample from heat deformation, the entire cutting process is liquid-cooled. The cooling liquid drains back into the coolant tank. For easy cleaning, the coolant tank is simple to remove.

Cut-off wheel cooling tank

Facts

Model types

Minitom is a low-speed precision cut-off machine for sectioning small and delicate materialographic workpieces that can’t tolerate the heat generated by high-speed cutting. It can handle various material types and comes with a universal specimen holder and flange set (65 mm diameter and 42 mm diameter).

Cut-off wheels, cutting fluid and additional specimen holders are ordered separately.

Specimen holder arm |

|

| Balance weight | 200 g / 7 ounces |

| Cutting weight | 350 g / 12 ounces |

Cut-off wheel | |

| Size | 75 - 125 mm / 3 - 5” |

| Arbor size | 12.7 mm / 0,5” |

| Rational speed | 100 - 420 rpm |

| Cutting capacity | 30 x 40 mm / 1.2” x 1.6” |

| Motor power | 38 W |

| Controls | Touchpad and turn knob |

| Recirculation cooling tank | 250 ml / 0.07 gallons |

| Noise level | LPA = 58 dB(A) |

| Surrounding temperature | 5 - 40° C / -13 -131° F |

| Humidity | Less than 95 % RH non-condensing |

Supply | |

| Voltage / frequency | 100 - 240 V / 50 - 60 Hz |

| Safety | In compliance with all relevant EU directives |

Dimensions and weight |

|

| Width | 28 cm / 11" |

| Depth | 40 cm / 15.7" |

| Height | 40 cm / 15.7" |

| Weight | 8 kg / 17.6 lbs. |

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Get your Technical Data Sheet for Minitom

Minitom Technical Data Sheet

A short and clear description that gives you an immediate overview to help you make the best choice of equipment.

• Capacity and performance specifications

• Dimensions and weight

• Electrical data

• Noice levels

• Safety

Get your brochure for Minitom

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory fotos

• Key feature descriptions

• Technical Data Sheet

Cutting consumables

-

Abrasive cut-off wheels

Extremely hard ferrous metal (500 < HV < 1400).

Go to webshop Contact sales -

Abrasive cut-off wheels

Very hard ferrous metal (400 < HV < 800).

Go to webshop Contact sales -

Abrasive cut-off wheels

Hard Ferrous metal (275 < HV < 750).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium hard ferrous metal (200 < HV < 550).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium soft ferrous metal (100 < HV < 500).

Go to webshop Contact sales -

Abrasive cut-off wheels

Soft ferrous metal (75 < HV < 375).

Go to webshop Contact sales -

Diamond cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

CBN cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

Additives for cutting

For recirculation, cooling and cleaning.

Go to webshop Contact sales -

+

-

−

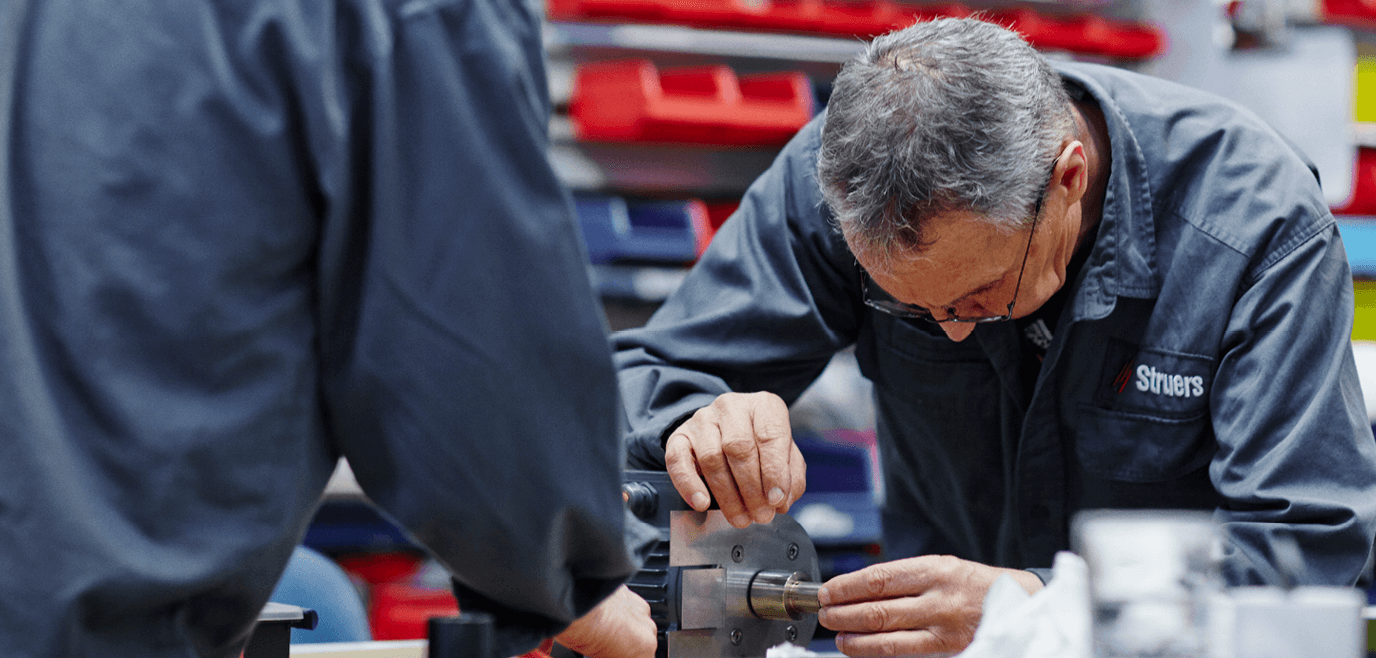

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

The backbone of our quality assurance program, our Struers laboratory promotes ease of use, resulting in high output and efficient use of our human resources and huge time savings. In my opinion, Struers equipment provides the most efficient and consistent method for examining the quality of our fastener products.Ideal Fasteners Pty. Ltd. (Australia) Neville Deutscher Managing Director

We have always experienced extremely repeatable and consistent, high-quality results. The consistency and reliability of our Struers cutting machines was instrumental in our decision to install a similar Struers system in our plant in Indonesia.Grinding Media, Moly-Cop (Australia) Glenn Sullivan Technical Developments Manager

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab