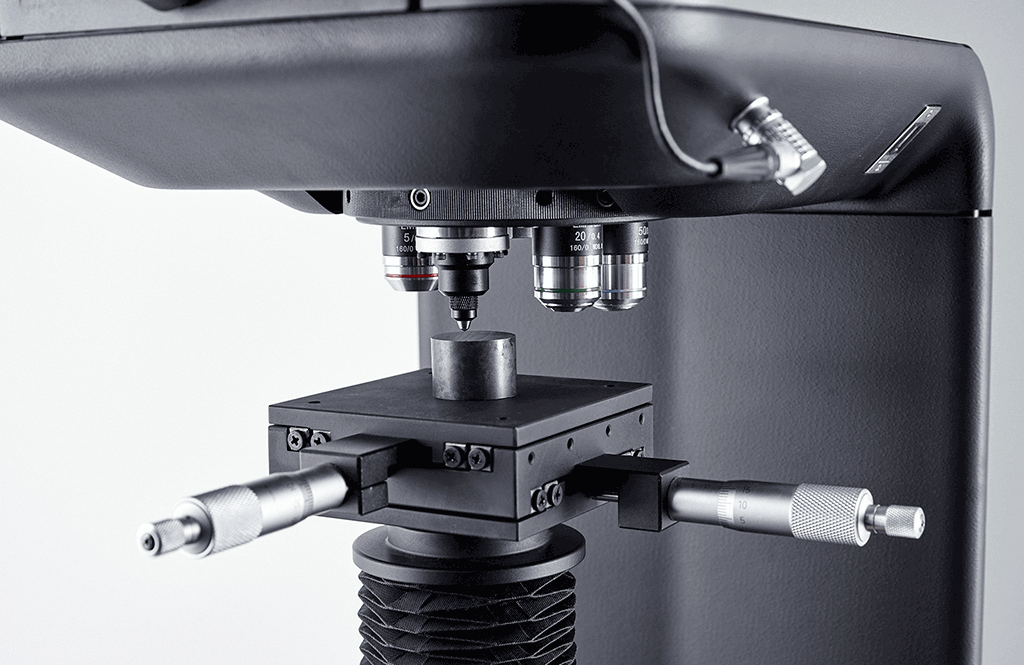

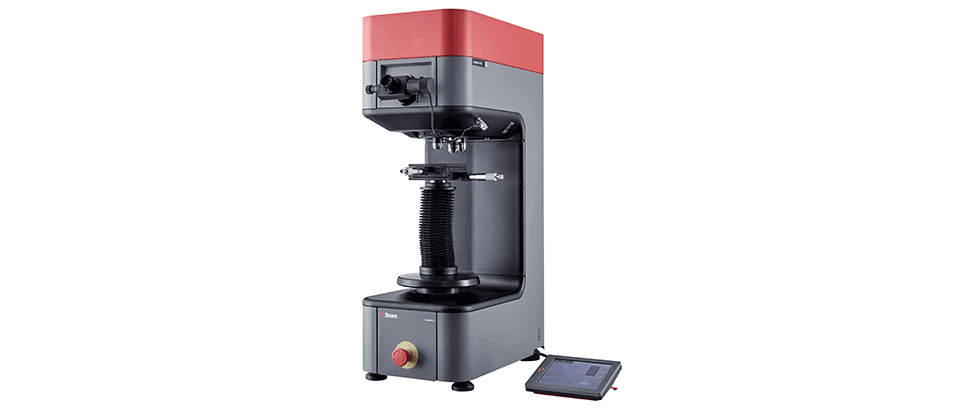

Accuracy and repeatability

Advanced load cell technology ensures that the Duramin-4 conforms to all operating standards, while offering consistent repeatability throughout the entire load range.

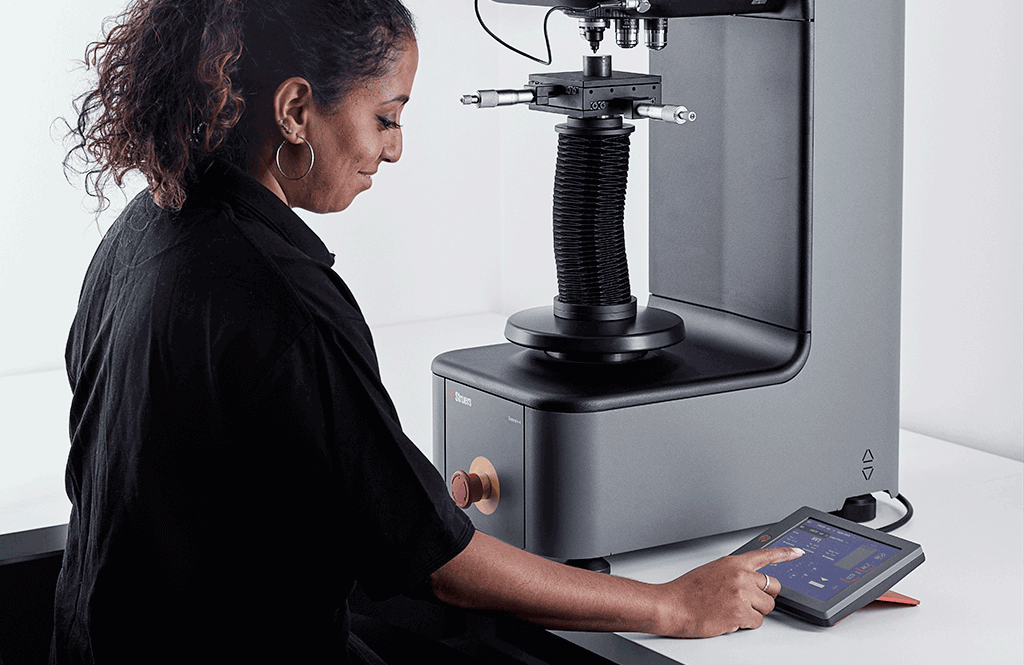

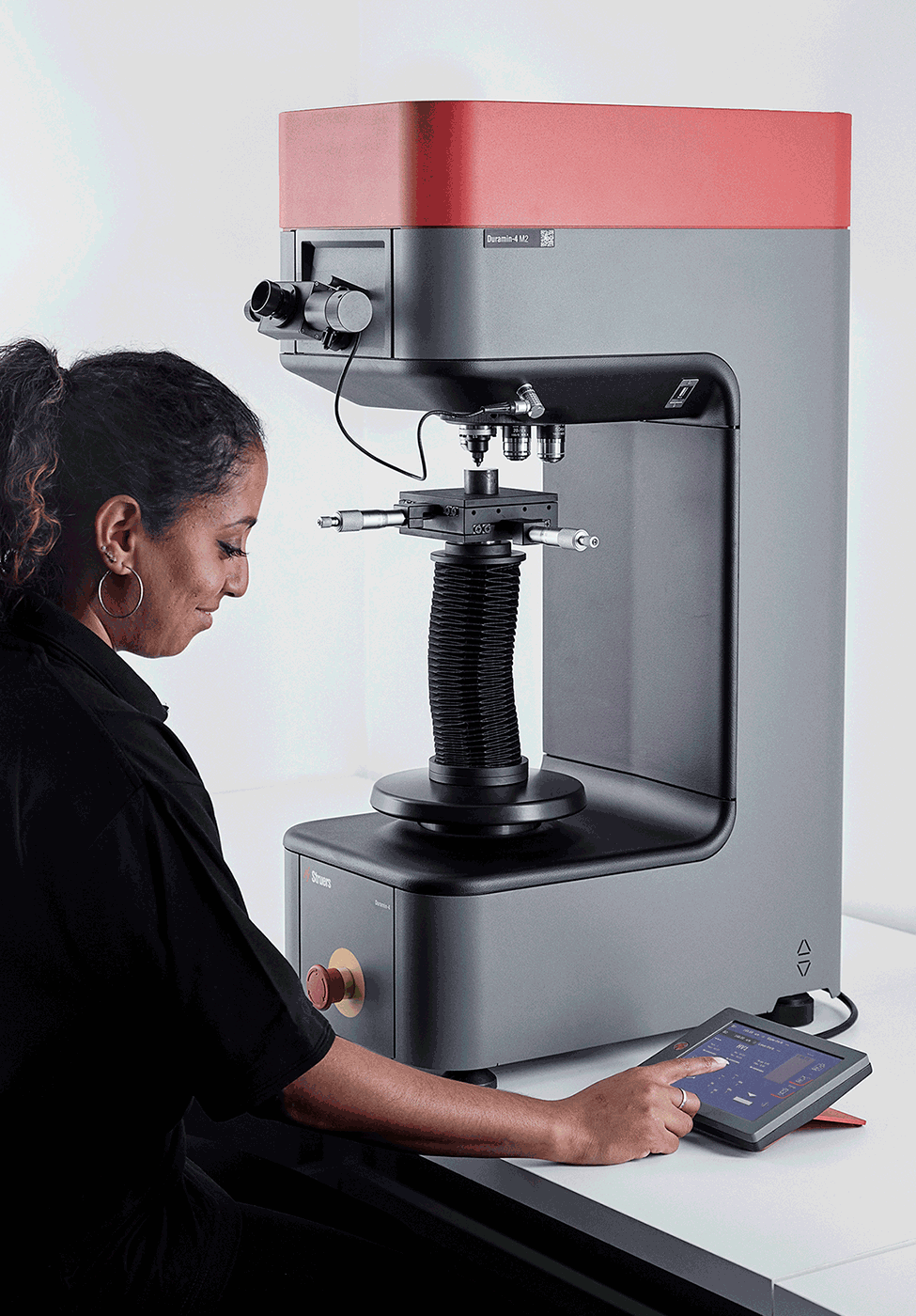

Easy operation

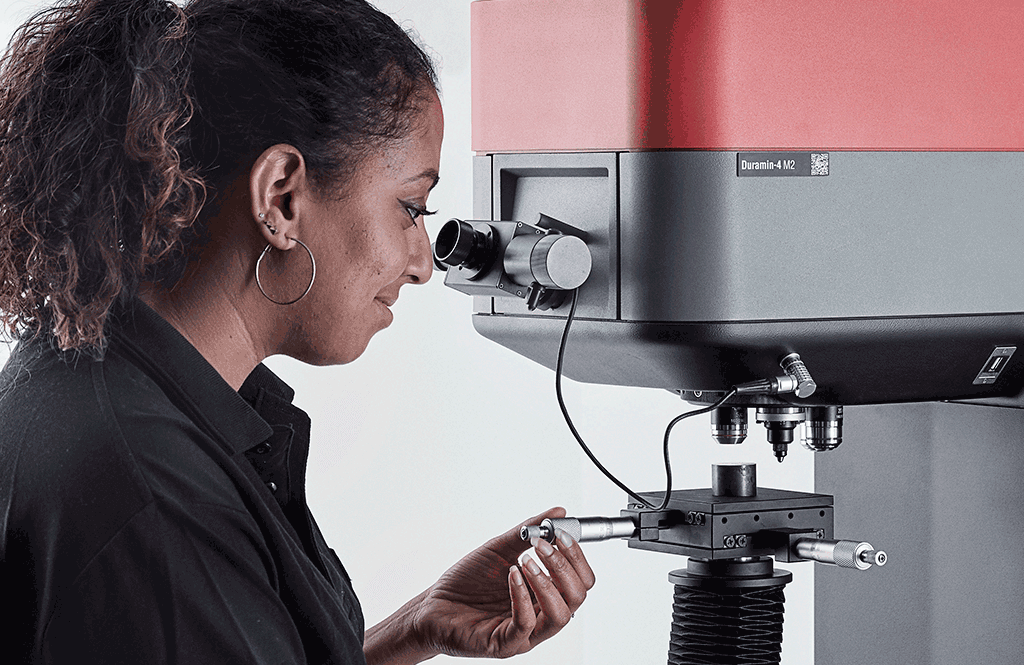

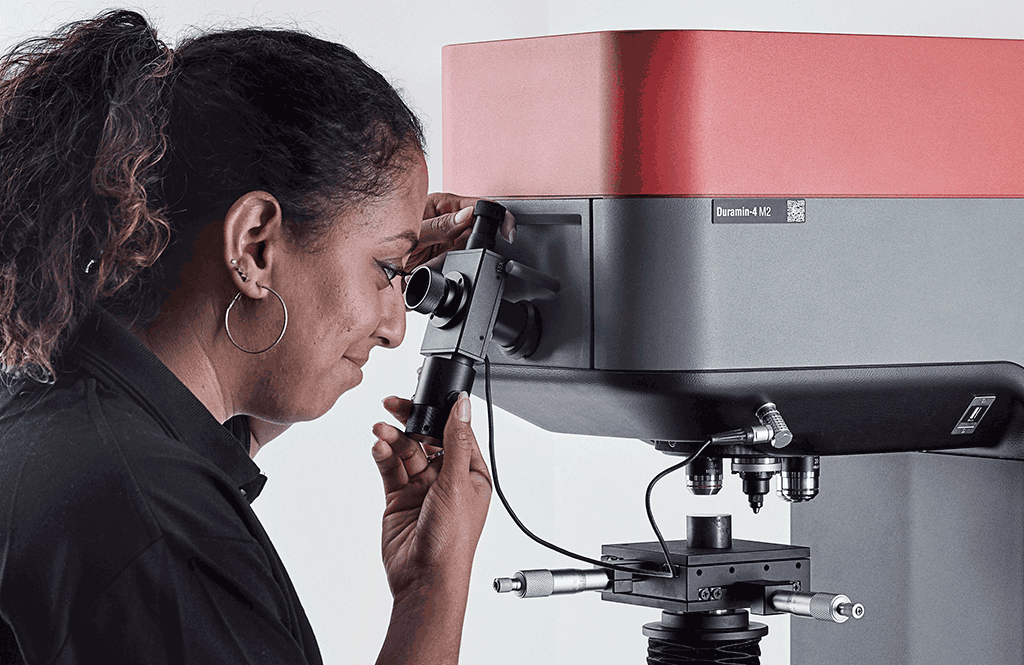

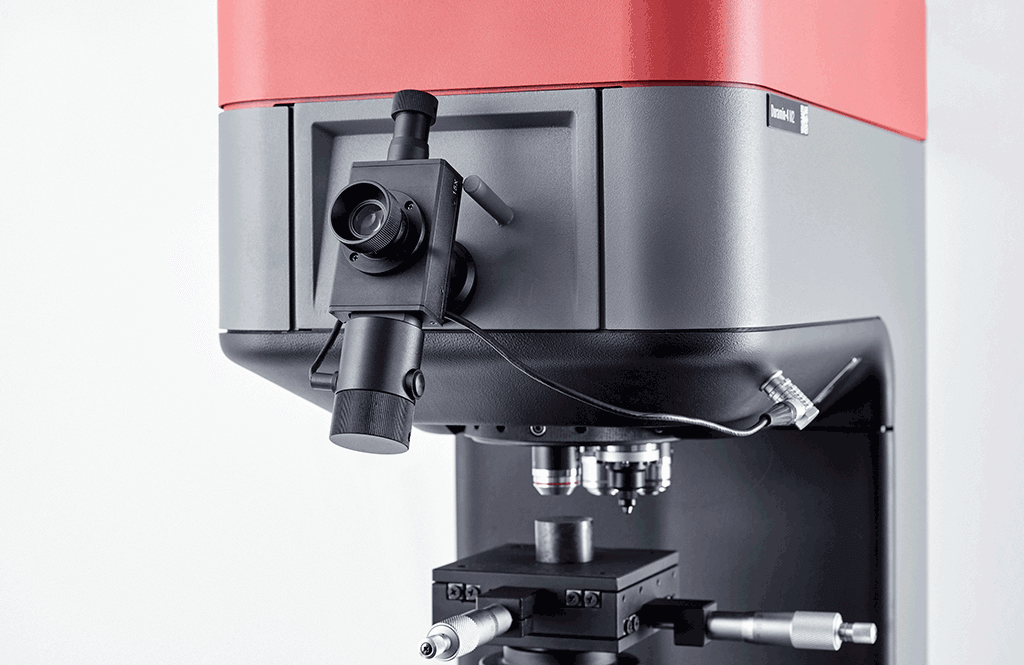

The display unit combines a touchscreen with a simple user interface, designed to be easy to use, yet robust enough to withstand the toughest production environment. The hardness evaluation takes place manually via an eyepiece, where the measurement lines are simply positioned around the indent.

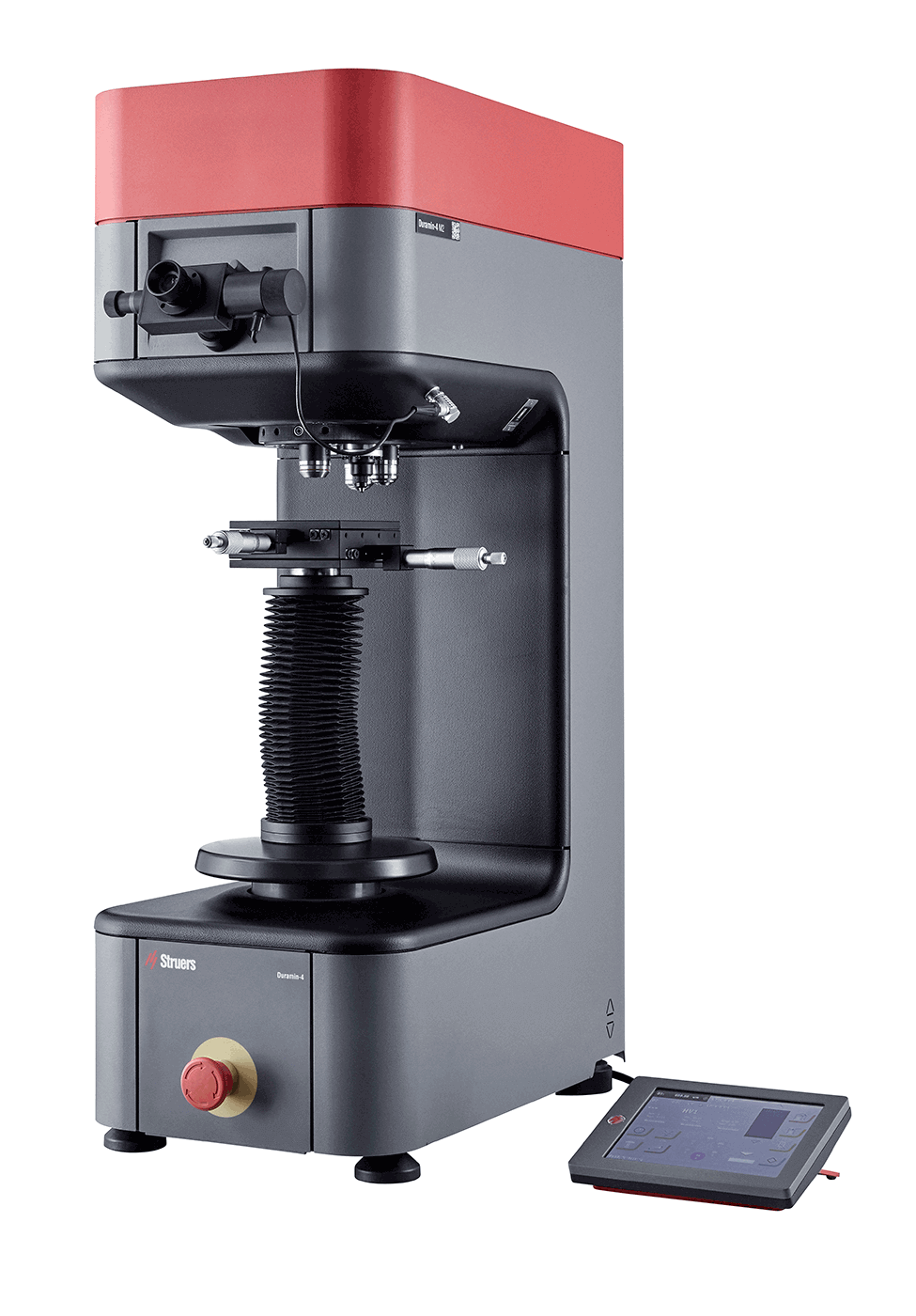

Dedicated solution

Duramin-4 is ideal for use as a dedicated Vickers single task tester, both in a laboratory (M1) or more production-focused (M2) environment.