Fast, dependable results for multiple applications

No matter what material you work with, with Struers you can be sure your lab has the right setup to meet the standards you need, with optimal reproducibility and repeatability of results.

Accurate hardness readings

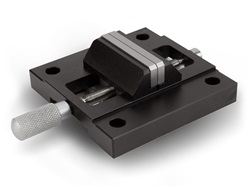

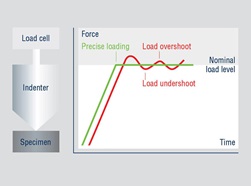

The DuraVigo-150 Rockwell hardness tester offers flexibility and conformity to ISO and ASTM standards with its permanent electronic test force monitoring and automatic test cycle. Its direct sub-micron depth gauging system, precisely aligned with the indenter’s axis, prevents measurement errors caused by system deformation. This ensures accurate and reliable hardness readings, making it an ideal choice for quality control in various industrial applications.

Enhanced Functionality and Connectivity

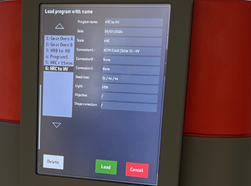

With enhanced functionality and connectivity, the new DuraVigo-150 facilitates effortless transfer of test results to various data storage mediums through its conveniently positioned USB port. Its 6.5” capacitive touch color display, ensures operational precision and swift response.

The accompanying software boasts an intuitive interface and large buttons, simplifying operation. Noteworthy features include high-/low-limit settings displayed in green and red, comprehensive statistics overview, and additional functionalities like hardness conversion and surface corrections, making it indispensable for quality control across diverse industrial sectors.