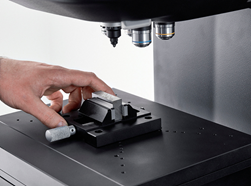

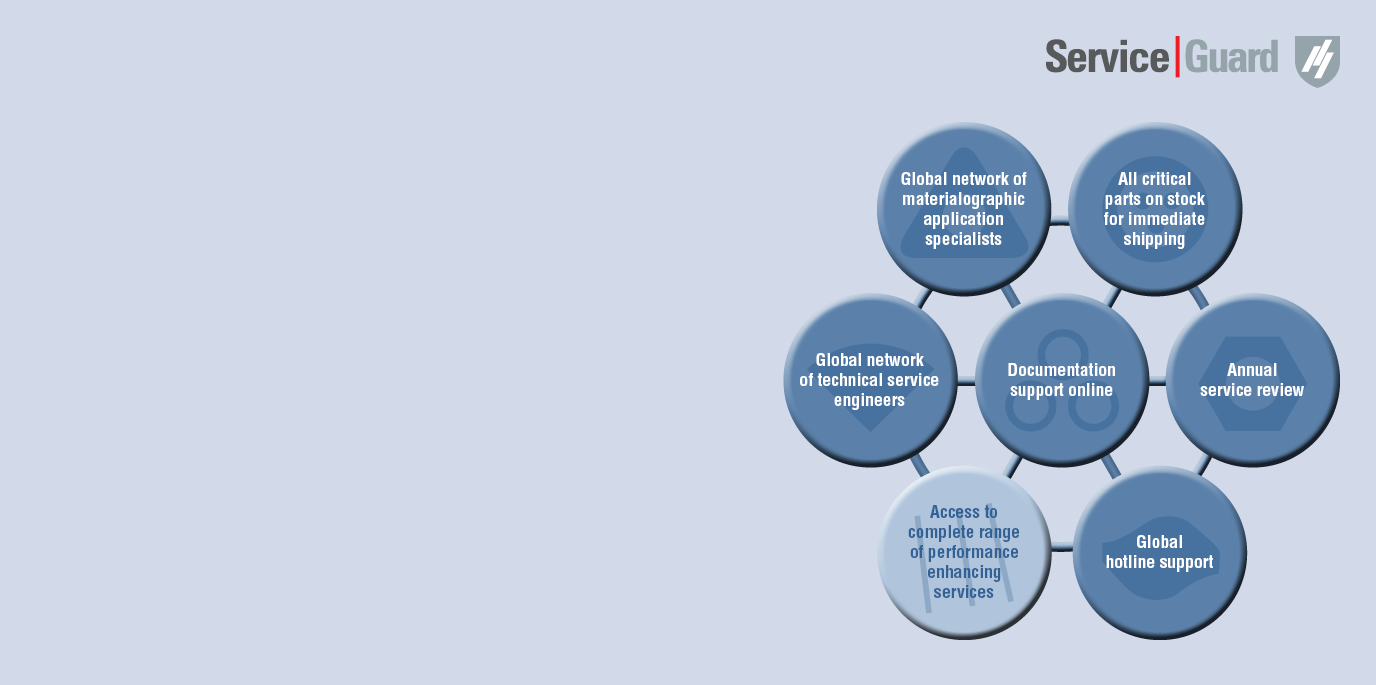

Fast, dependable results for multiple applications

No matter what material you work with, with Struers you can be sure your lab has the correct setup to meet the standards you need, with optimal reproducibility and repeatability of results.

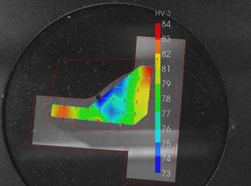

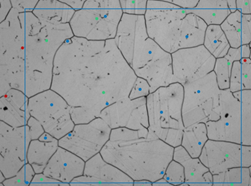

Unique functionalities for superior results

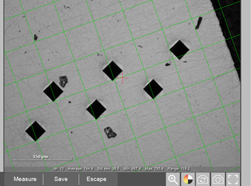

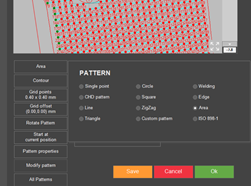

Use the overview camera for fast positioning of the pre-programmed patterns and let the DuraVista do all indent and measurement work unattended. Higher and more reliable throughput without the need to hire more lab staff.

Built for your Business

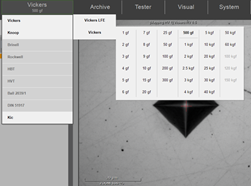

Both hard- and software were designed to comply with ISO and ASTM standards fully from the load mechanics, the optical system, and the high-resolution camera to the advanced software algorithms. The Z-axis is controlled with a precision ball screw spindle for a fast and precise movement for focus and positioning. Unique in its class.