Recorded Webinar

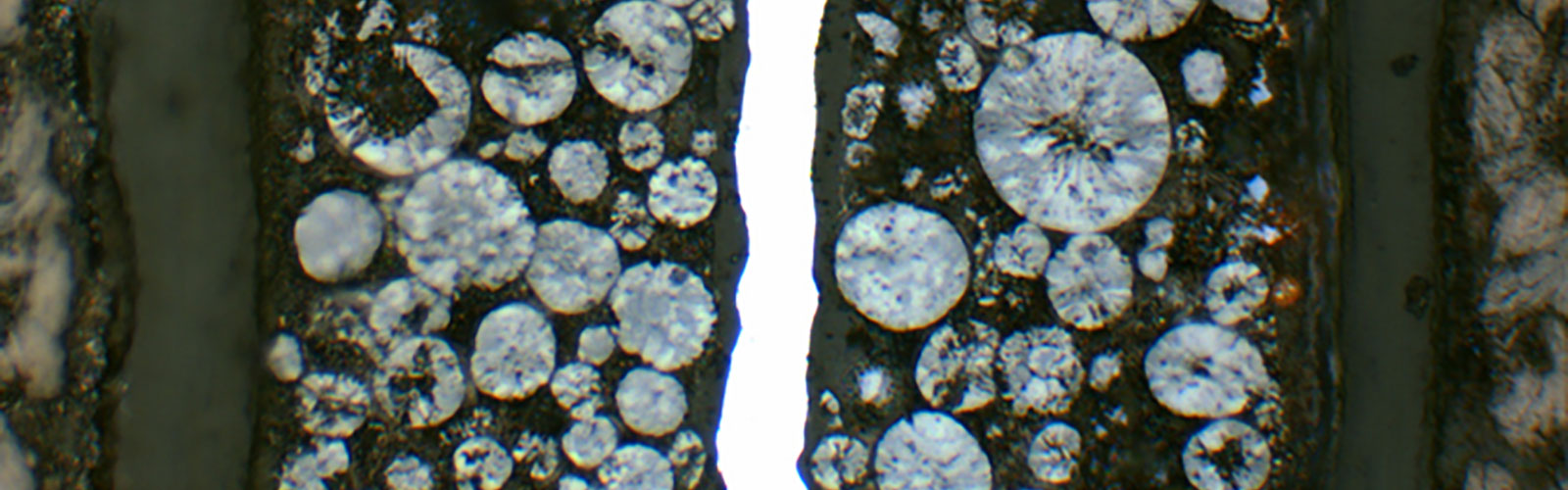

Nodularity Measurement Using Image Analysis and Its Correlation with Mechanical Properties of Ductile Iron

Are old verification practices slowing you down?

High ductility makes ductile (spheroidal-graphite) iron suitable in the manufacture of safety-critical parts such as: axles, crankshafts, steering knuckles, hubs, differential carriers, brake calipers, transmission parts, valves, etc. To achieve high ductility, the as-cast structure of ductile iron contains graphite particles in small rounded, “spheroidal”, “globular”, or “nodular” form. The mechanical and physical properties depend on the graphite being predominantly or wholly in the spheroidal (nodular) shape. Evaluation of the cast product and control of the production process therefore depend on the accuracy and reproducibility of the measurement method.While visual estimation of nodularity and nodule count has been a long-standing practice, it suffers a major setback of poor reproducibility and repeatability. Image analysis method per ASTM E2567-16a provides accurate and repeatable results that are not subject to operator inclinations. These results can be obtained in a matter of minutes compared to mechanical properties which can take hours and sometimes even days. The correlation between nodularity and mechanical properties enables furnace operators to qualify a heat of ductile iron in a timely manner thereby boosting foundry productivity.