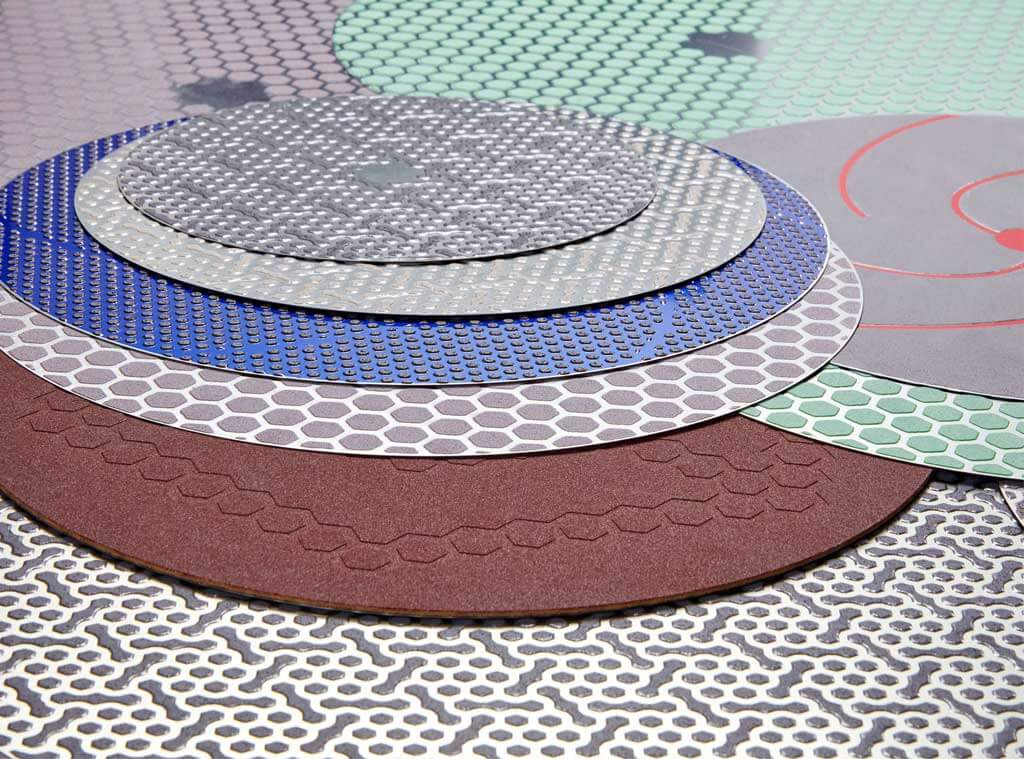

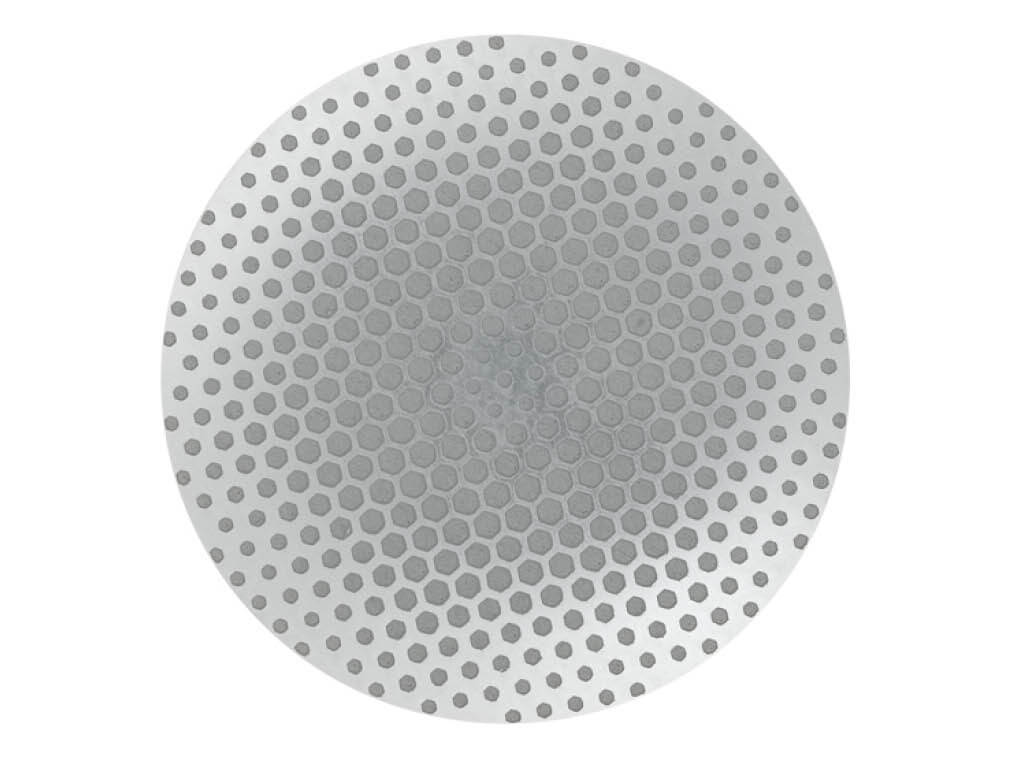

How can MD grinding surfaces support your materialographic process?

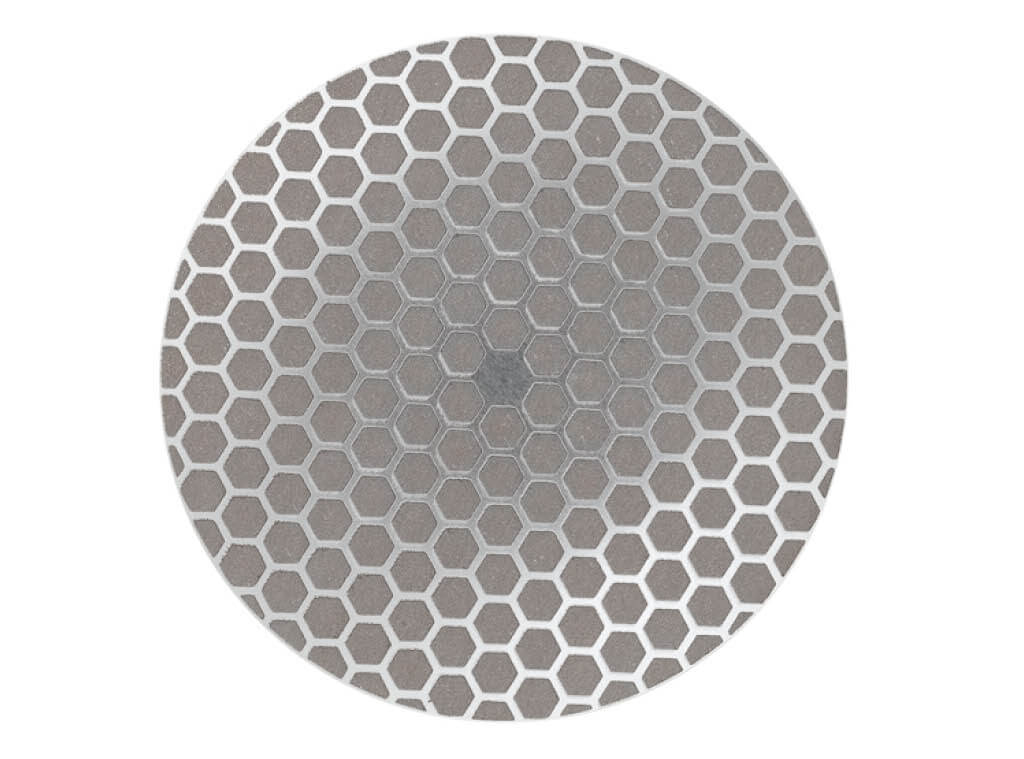

Achieve superior preparation results

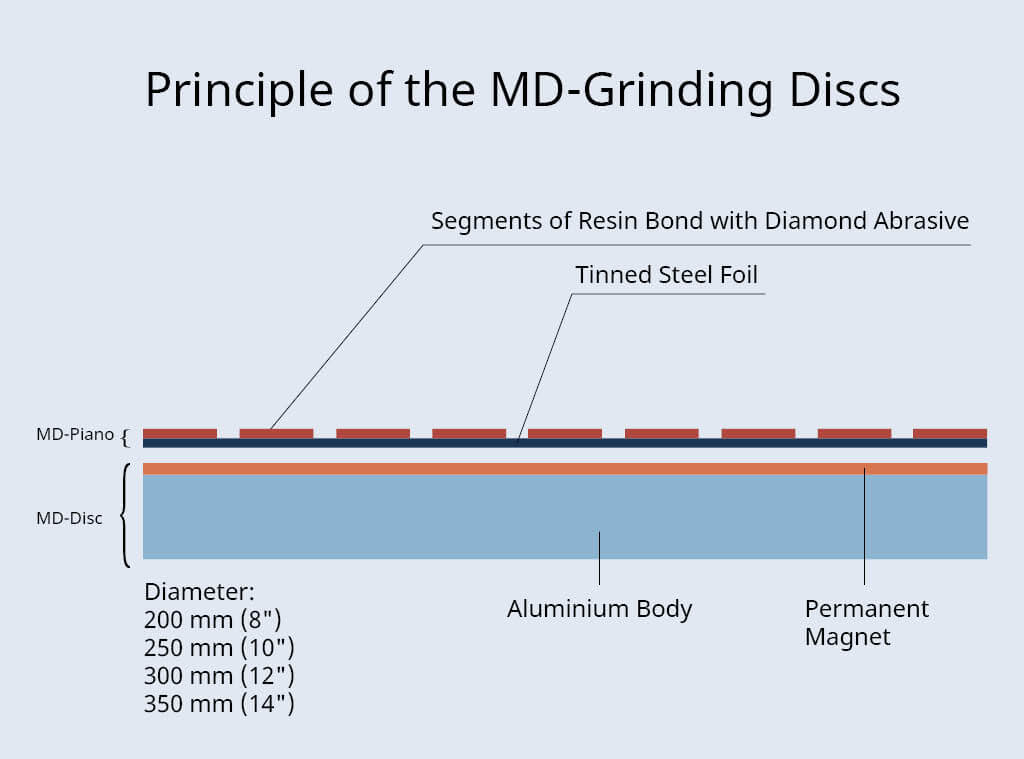

If you are looking for high quality preparation results with virtually no artifacts, MD surfaces are ideal for you. The rigid MD surface offers no resilience, achieving a plane specimen and avoiding edge rounding. It also ensures uniform material removal with no smearing in soft phases or chipping in brittle phases.

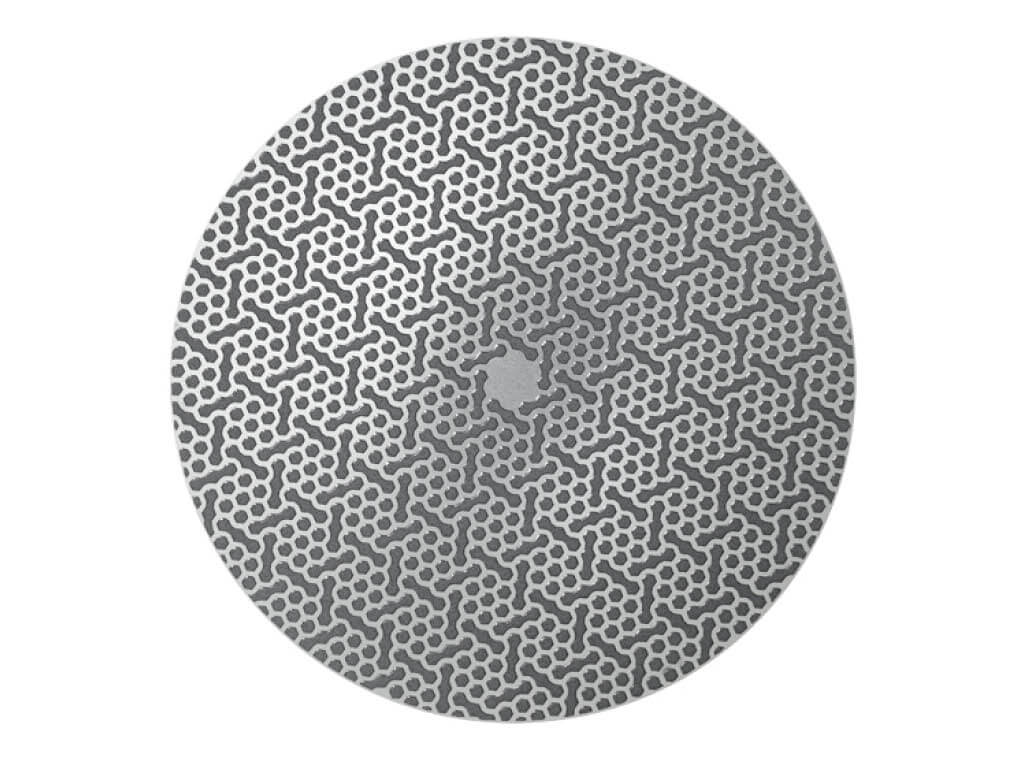

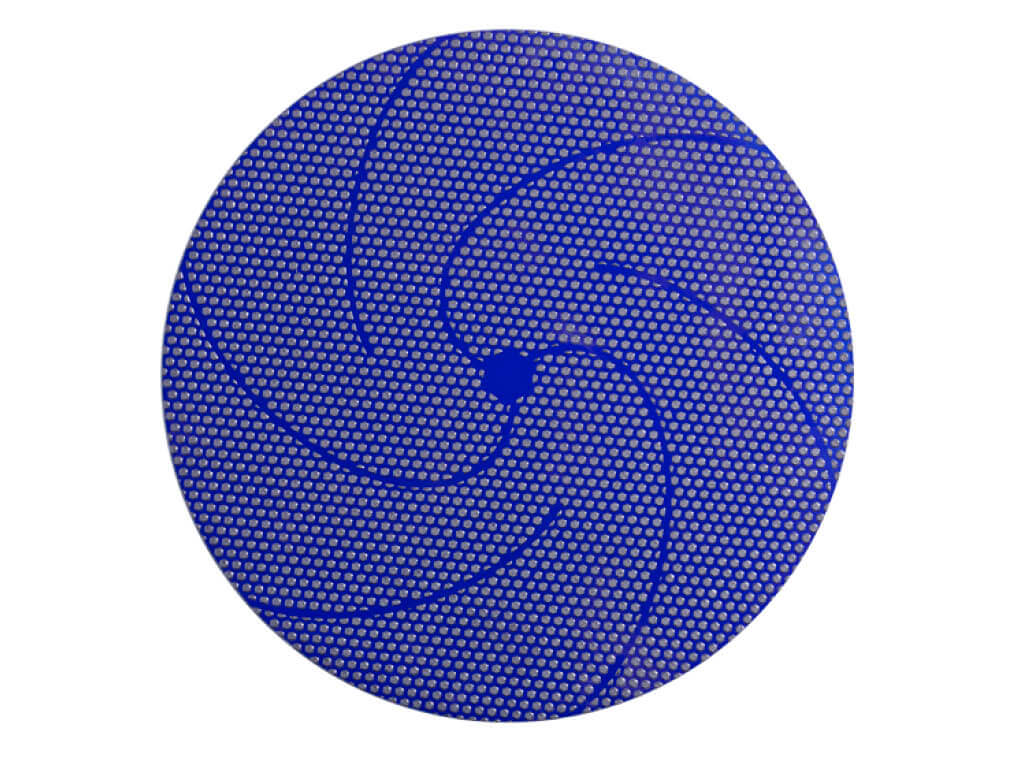

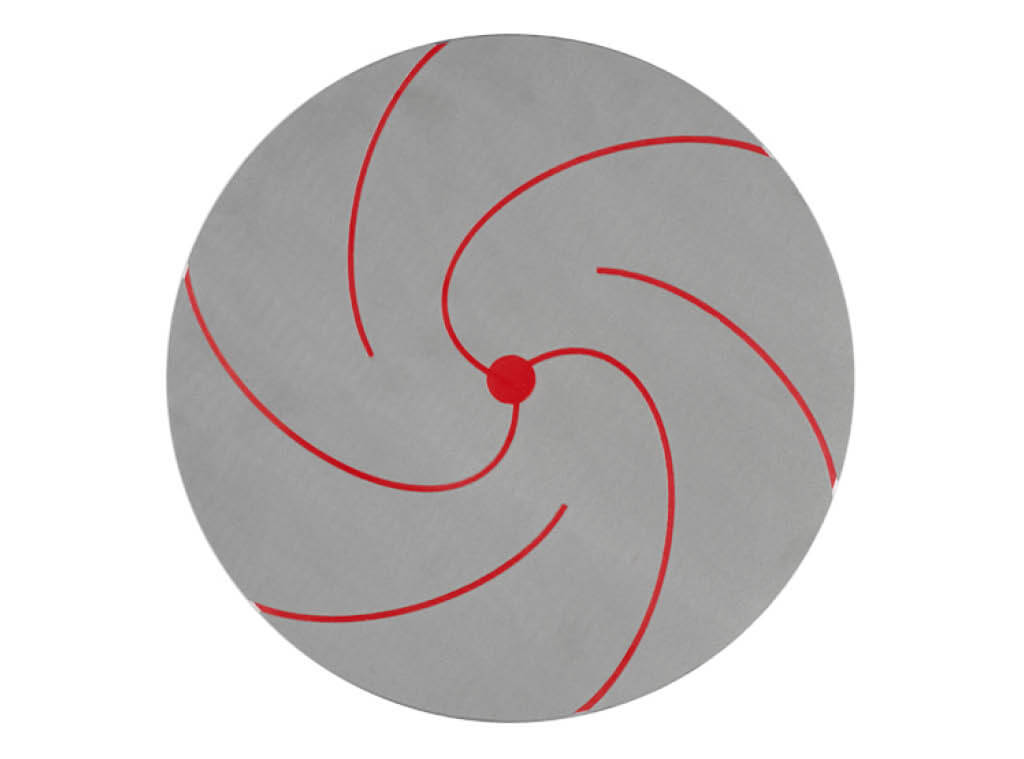

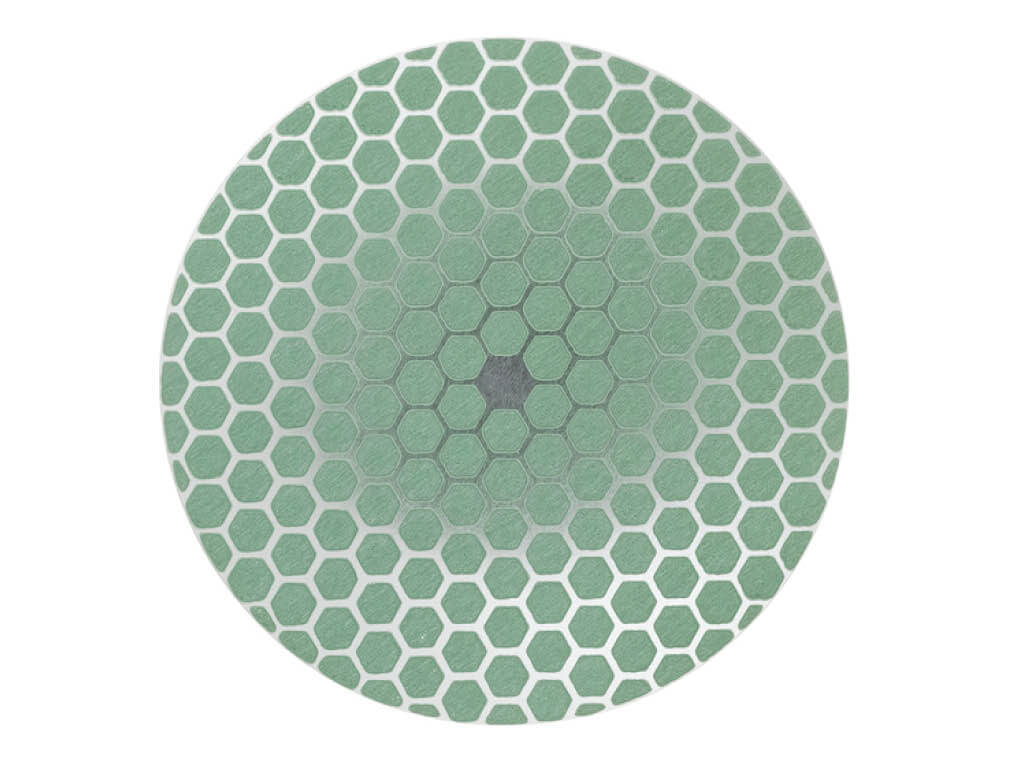

Find a surface optimized to your material

When you work with a specific material, why compromise on an all-round solution? Each of our MD surfaces is optimized for a dedicated material group. You are sure to find an MD surface for your material from our wide range. The unique combination of pattern, abrasives and bonding for each surface provides consistently high removal while causing minimal deformation. As a result, you can reduce the time spent on your following steps by up to 50 %.

Minimize errors and maximize reproducibility

Support a robust, standardized process by eliminating both random errors and human errors. The ready-to-use MD surface reduces the complexity of your process and its consistent removal ensures reproducible results – time after time.

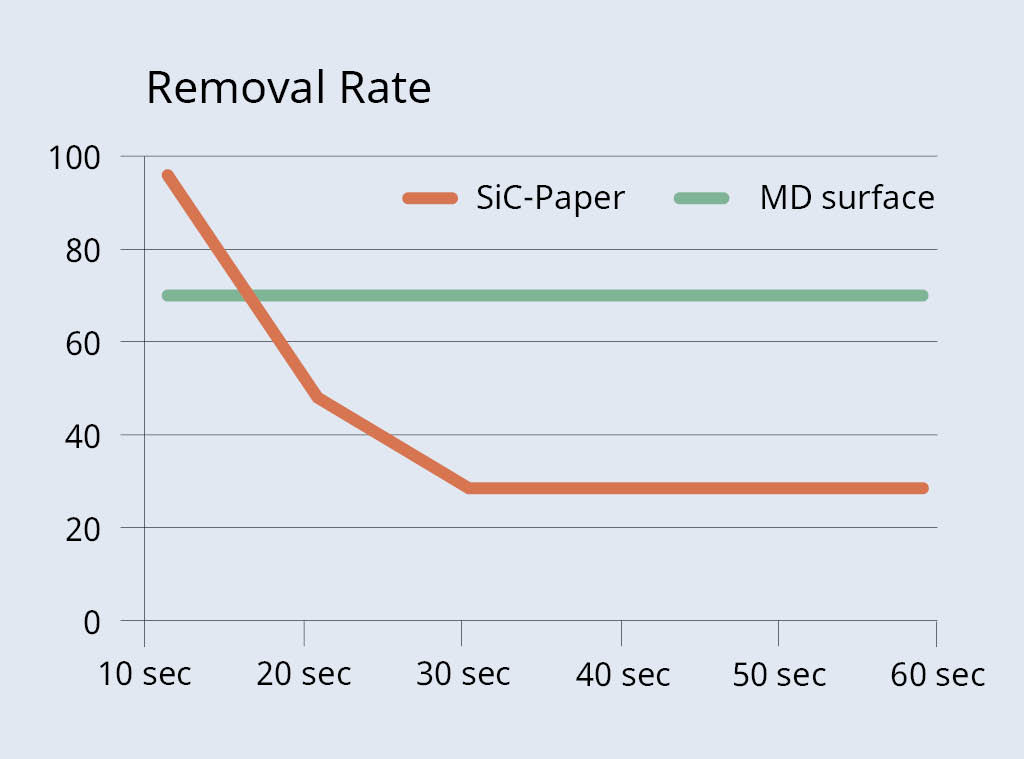

Reduce your process waste in changing surfaces

What if you could free up an operator while your automated equipment does the job? The durable MD surface lasts significantly longer than SiC Foils or Papers, and does not need replacing as frequently which will reduce your process waste and maximize your efficiency.